Why Contamination Control is Non-Negotiable

Contamination poses a serious risk in cleanrooms, where even microscopic particles or microbes can compromise product quality, patient safety, and regulatory compliance. It can lead to costly product recalls, production downtime, and reputational damage. Strict contamination control measures are essential to prevent cross-contamination, maintain cleanroom classifications, and meet GMP and regulatory standards.

Rising regulations such as updated EU GMP Annex 1, increasing FDA scrutiny, and stricter ISO cleanroom standards are putting greater pressure on cleanroom facilities to tighten contamination control. These regulations demand more robust environmental monitoring, data-driven validation, and proven control methods to ensure sterility and product integrity, making outdated or ineffective practices harder to justify.

Many companies may think they are covered, but common mistakes can still slip through the cracks, leading to significant consequences.

Mistake One: Relying on Disposable Sticky Mats

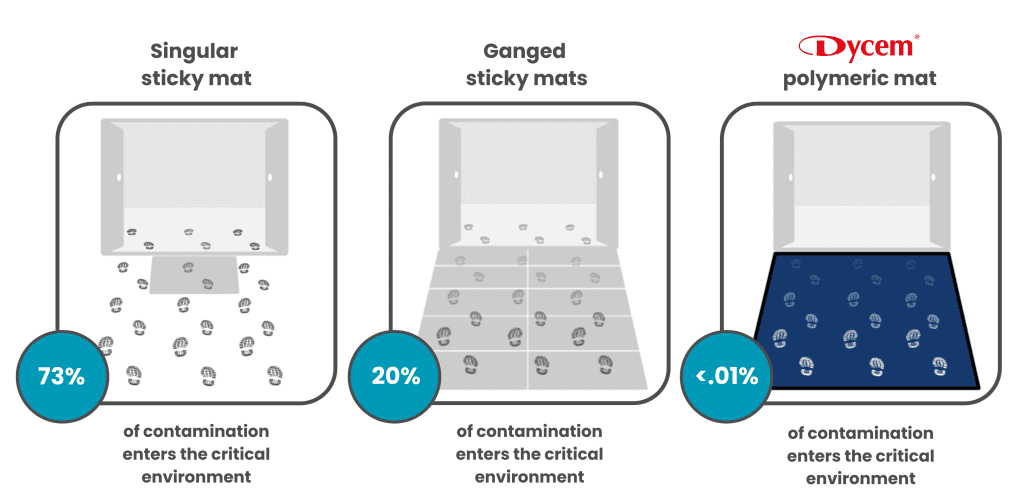

Why it’s a Problem: Sticky mats are only 27% effective (Clibbon, 2002) at capturing contamination, leaving critical areas exposed to significant risk. To maintain even minimal performance, they require frequent peeling, which releases thousands of trapped particles back into the air during removal. These mats also generate large volumes of contaminated waste, making disposal both costly and environmentally unfriendly. They are incompatible with wheeled traffic, as the adhesive surface sticks to and wraps around wheels, creating operational issues. Worse still, adhesive residue can be tracked into controlled environments, introducing further contamination risks rather than preventing them.

How to Avoid It: Switch to high-performance polymeric mats like Dycem, a naturally tacky, adhesive-free solution proven to capture and retain up to 99.9% of contamination from shoes and wheels, and up to 75% of airborne particles. With an average lifespan of 3–5 years, Dycem mats are a more sustainable and cost-effective choice compared to disposable alternatives. They also offer added protection through built-in antimicrobial and static-dissipative properties, making them ideal for maintaining cleanliness in critical environments.

Mistake Two: Poor Zoning and Workflow Design

Why It’s a Problem: Poor zoning and workflow design can lead to cross-contamination when clean and dirty areas aren’t clearly defined. Without clear boundaries, staff may unknowingly move from uncontrolled to controlled zones without proper decontamination. For example, if a food production facility fails to separate raw and cooked zones, it may face repeated audit issues and the risk of costly recalls.

How to Avoid It: To avoid cross-contamination caused by poor zoning, implement clear visual cues such as floor markings, signage, and colour-coded contamination control mats. Dycem mats are available in a range of colours, allowing you to easily differentiate between clean and dirty zones, entry and exit points, or specific production areas, helping staff visually identify boundaries and reduce the risk of accidental breaches. Combine this with employee training on movement protocols and regular audits to assess layout efficiency and identify contamination risks.

Mistake Three: Inconsistent or Inadequate Staff Training

Why It’s a Problem: Inconsistent or inadequate staff training is a major risk, as people are the biggest source of contamination. Even with the most advanced equipment in place, its effectiveness is greatly reduced if staff aren’t properly trained on how to use, maintain, or move through controlled areas. Without regular, reinforced training, procedures can be overlooked, increasing the risk of contamination events that compromise product quality and regulatory compliance.

How to Avoid It: To avoid issues caused by poor training, implement a comprehensive contamination control training program for all staff, starting at onboarding and continuing through regular refreshers. Focus on correct gowning procedures, movement protocols, hand hygiene, and proper use of contamination control equipment. Include the “why” behind each step so employees understand the impact of their actions on product quality and safety. Reinforce learning with visual reminders in key areas and conduct routine audits or spot checks to ensure procedures are being followed consistently.

Mistake Four: No Regular Validation or Performance Monitoring

Why It’s a Problem: Failing to regularly validate or monitor contamination control performance can lead to a false sense of security. You can’t manage what you don’t measure, yet many facilities install control measures and assume they’re working without ongoing verification. Over time, even the most reliable systems can become less effective due to wear, improper use, or changes in workflow. Without regular audits, particle monitoring, or surface testing, issues can go unnoticed until they result in product failures or regulatory breaches. Continuous monitoring is essential to ensure that contamination control strategies remain effective and compliant.

How to Avoid It: To avoid this mistake, establish a structured validation and performance monitoring program as part of your contamination control strategy. Regular environmental monitoring, such as particle counts, surface swab tests, and airflow validation, is essential to ensure control measures are working effectively. For physical barriers like Dycem mats, incorporate routine visual checks and cleaning audits. Dycem also offers free annual performance testing to help facilities validate the effectiveness of their mats, identify potential risks, and ensure continued compliance with cleanroom standards.

Mistake Five: Ignoring Contamination from Wheeled Traffic

Why It’s a Problem: Ignoring contamination from wheeled traffic is a common oversight, as many contamination control measures focus solely on foot traffic. However, wheeled items like trolleys and carts can track large amounts of particulate deep into clean zones, posing a serious risk.

How to avoid It: Designate clean and dirty trolleys for different zones, and ensure all wheeled items follow defined routes. Installing high-performance polymeric mats like Dycem WorkZone is a highly effective solution. Specifically engineered for heavy-duty wheeled traffic, Dycem WorkZone mats can capture up to 99.9% of contaminants from wheels, significantly reducing the risk of particles being tracked into critical areas. Placing these mats at all transition points and equipment entryways ensures that both shoes and wheels are decontaminated before entering clean zones.

The Cost of Overlooking the Details

Overlooking even small details in contamination control can result in failed audits, costly product recalls, and serious safety incidents. By avoiding these five common mistakes, you can significantly strengthen your contamination prevention efforts and protect both your products and your reputation. Whether you are establishing a new clean zone or upgrading an existing facility, success depends on combining the right tools with disciplined procedures and ongoing staff engagement to maintain a consistently controlled environment.

Get in touch to learn how Dycem mats could help strengthen your contamination control strategy.