Food and Beverage

Manufacturers in the food and beverage industry are being asked to meet more stringent hygiene standards to prevent contamination. Dycem’s contamination control mats offer antimicrobial benefits for this sector, offering long-lasting, highly effective protection for critical areas. These mats help ensure that food safety protocols are met at every level, safeguarding products, processes and people.

Where to use Dycem in the food & beverage industry

Prep & Packaging Areas

High-Care Zone Entries

Locker Room Entry/Exits to Production

Kitchens/ Catering Facilities

Allergen Sensitive Areas

Raw Material Entrances

In Between Production Lines

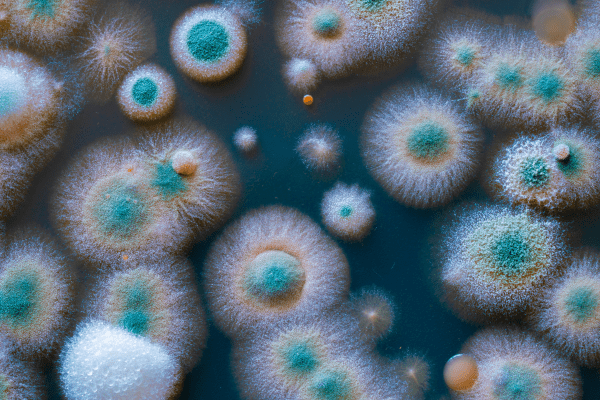

Contamination In The Food & Beverage Industry

Controlling contamination is critical in the food and beverage industry, especially during production, processing, and packaging.

The most common sources of contamination are operators, equipment, and environmental factors, which can lead to biological, physical, and chemical risks.

Tricky microbial contamination from Salmonella, Listeria, and E. coli, poses severe risks to consumer health, product integrity, and brand reputation.

Effective contamination control, such as using Dycem antimicrobial mats, is essential to minimizing these hazards and ensuring food safety.

Don't Ignore the Floor...

80% of Contamination Enters a Critical Space at Floor Level.

Benefits of Dycem in the Food Industry

Customized hygiene level control

Dycem mats come in various colors to designate hygiene levels and guide operator behaviors. Custom floor graphics can also help communicate risks effectively.

Reduced microbial contamination concerns

With antimicrobial properties, Dycem mats provide peace of mind by stopping reproduction at the source.

Low Maintenance, dry alternative

Unlike wet or powder-based solutions, Dycem mats are lower-maintenance, lasting over 3+ years, and offering minimal downtime during daily cleanings.

Food Industry Contamination Control Solutions

In the food and beverage industry, maintaining contamination-free production and packaging spaces is crucial. Dycem offers highly effective antimicrobial solutions tailored to meet the elevated safety standards required in these environments.

Our solutions include contamination control mats for food factories, commercial kitchens, and food prep areas. We also provide antimicrobial bench mats and push pads to manage contamination risks at all levels, ensuring your facility remains protected from start to finish.

Dycem CleanZone

CleanZone helps control contamination from the shoes of personnel.

Dycem WorkZone

WorkZone is the only effective solution for decontamination of heavy wheels.

In Your Industry

Discover your industry’s specific applications—all conveniently summarized right here.

Success Stories...

Discover our success stories for contamination control flooring in the food industry.

Learn how our customers have benefitted from installing Dycem in food prep areas.

Preventing Contamination in Food Manufacturing

Read this guide from Remax Food Products to strengthen the contamination policy in your facility:

“Because personnel handle the food in your warehouse, their practices are closely tied to food safety from contamination. It is the job of the manager in food operations to ensure that all personnel comply with the official contamination policy. To do this managers must oversee the training of personnel on food protection principles and food handling techniques. A training program for permanent, temporary, as well as contract employees needs to be created, evaluated each quarter, and updated if necessary.”