Cleanrooms play a critical role in nanofabrication, where even microscopic particles can disrupt production processes and compromise product quality. To address these challenges, the National Graphene Institute (NGI) at the University of Manchester operates a state-of-the-art 1,500 m² cleanroom suite. This advanced facility is equipped with a broad range of nanofabrication and characterisation tools, specifically designed for work involving 2D materials, such as graphene.

Recognising the importance of stringent contamination control to protect the integrity of their cleanroom environment, NGI sought innovative solutions to enhance contamination management at critical entry points.

CHALLENGE

The NGI faced challenges with expired alternative polymeric mats, which failed to effectively contain contaminants before entering the cleanroom.

To combat this issue, NGI installed additional disposable sticky mats at critical points throughout the facility. However, while these mats improved containment, they increased costs, generated a high volume of contaminated waste, and caused floor damage due to residual adhesive.

SOLUTION

At the NanoFab UK conference, NGI representatives met with Dycem’s contamination control specialists, who presented Dycem’s polymeric mats clearly and concisely. This allowed NGI to gain a first-hand understanding of the product’s effectiveness and ease of maintenance. Impressed by the demonstration and Dycem’s reputation as a trusted solution used by companies worldwide, NGI chose to replace their expired alternative polymeric mats with Dycem polymeric mats and eliminated the need for additional sticky mats.

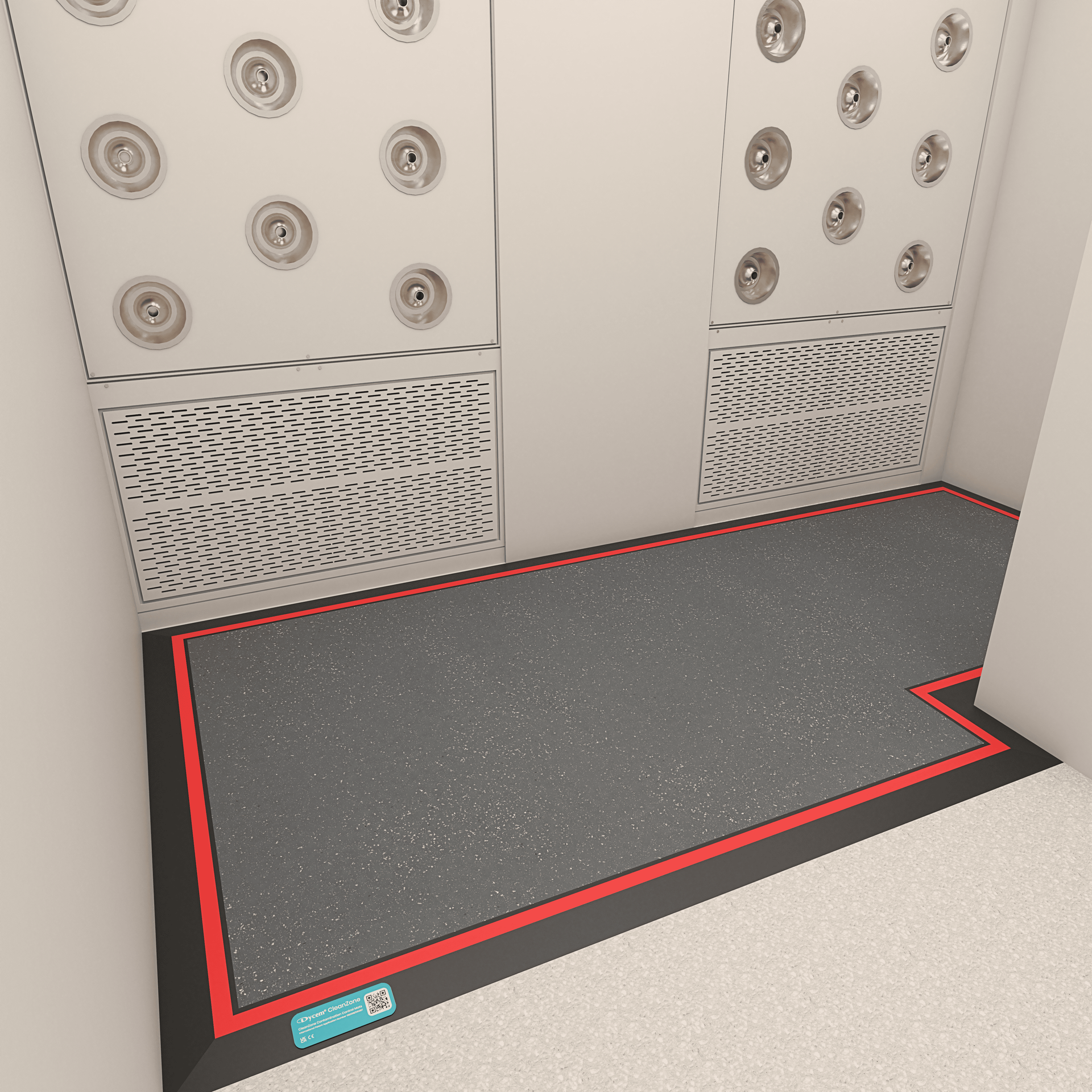

NGI opted for Dycem CleanZone mats in the colour Midnight, strategically placing them throughout the facility. Key locations included cleanroom entrances, pre-change areas, and staging area entrances, ensuring optimal contamination control across the site.

RESULTS

The Dycem mats offered a solution that NGI found was easy to clean and maintain, requiring minimal effort to keep them in optimal condition. The NGI team created a rota to ensure the mats are adequately sustained, cleaning them twice a day, and incorporating regular inspections by the facility manager.

Additionally, the mats have improved contamination containment, effectively trapping floor-level particulates and debris before they can enter the cleanroom, thereby enhancing the overall cleanliness and performance of the controlled environment.

By eliminating the need for disposable sticky mats and reducing waste, the switch to Dycem mats significantly lowered NGI’s annual consumable costs, contributing to a more sustainable and cost-effective contamination control solution.

“Using Dycem’s services has been an entirely positive process with incredible communication and cooperation from everyone involved. Since installation, the Dycem mats have done a fantastic job at containing contamination ensuring our cleanroom facility maintains its ISO classification. The mats are also easily cleaned within a few minutes using cleaning products provided by Dycem. Overall, I would highly recommend this company and the product supplied.” – Matthew Whitelegg, Senior Cleanroom Technician

ABOUT NATIONAL GRAPHENE INSTITUTE

The National Graphene Institute (NGI) is a £61M facility that serves as a hub for over 280 users from academia and industry, fostering collaborations with an extensive network of national and international partners. Combining ground-breaking research in 2D materials with cutting-edge equipment and engineering expertise, NGI offers an unmatched platform for advancing scientific discovery and driving innovation in partnership with industry leaders.