R.W. Simon is a UK-based manufacturing company operating from its site in Torrington, Devon. The business consists of two specialist divisions:

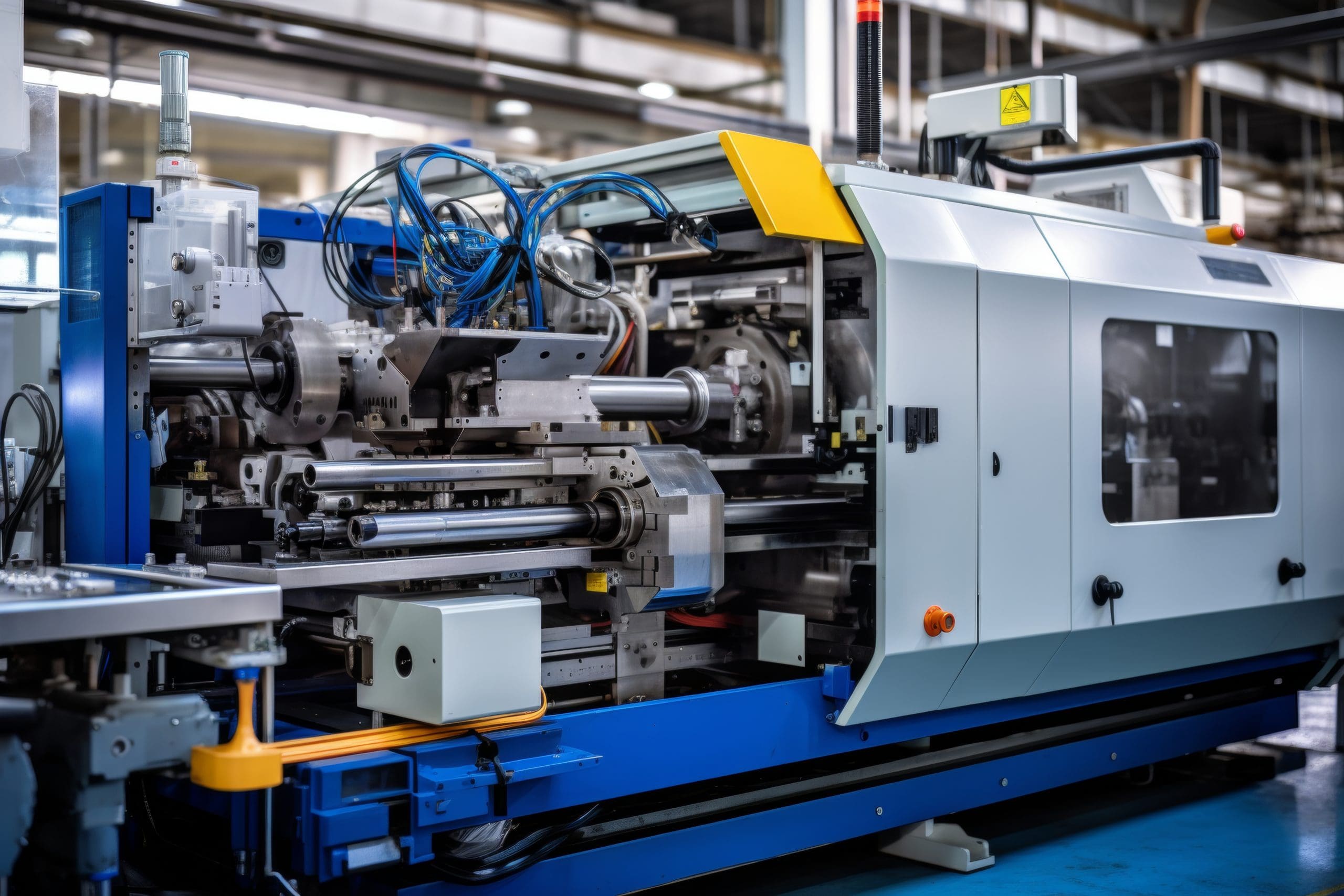

- Plastics Division – Focused on the design, development, and manufacture of thermoplastic mouldings.

- Aluminium Building Product Division – Experts in window ventilation systems, solar shading solutions, and Louvre screening.

As customer expectations and industry standards continue to rise, particularly in sectors where product consistency, durability, and performance are critical, R.W. Simon is committed to strengthening its internal processes. A key part of this is adopting stricter cleanliness and contamination control protocols across its manufacturing environment.

CHALLENGE

Contamination poses serious risks to manufacturing environments, especially in processes like plastic moulding. Dust and fibres can cause product defects, trigger rejections or recalls, and ultimately damage operational efficiency and brand reputation.

With growing pressure from clients and regulators to demonstrate tighter quality control, the company recognised the importance of tackling even microscopic contaminants like dust and fibres. These can compromise product performance or lead to costly internal non-conformances. By investing in contamination control solutions, R.W. Simon is proactively positioning itself to exceed industry standards and uphold its reputation for quality and reliability.

SOLUTION

Dycem came highly recommended for product quality, industry knowledge, and overall professionalism. After receiving this recommendation from an existing Dycem customer, R.W. Simon explored the benefits of Dycem’s contamination control flooring. R.W. chose Dycem for its proven ability to significantly reduce contaminants from shoes and wheels (up to 99.9%), as well as its sustainable, reusable nature.

The facility integrated Dycem’s CleanZone and WorkZone contamination control mats into its workflow, with 10–20 employees using them daily. The team found the cleaning equipment provided by Dycem highly effective and easy to use, thanks to clear instructions that help them consistently maintain best practices. You can see one of the mats we installed below, or watch the installation video here.

RESULTS

Since installing Dycem, R.W. Simon has seen a clear reduction in fibre and dust contamination within its facility. This has directly contributed to an improvement in internal quality results and a decrease in non-conformances. The company highlighted that removing Dycem from their workflow would be considered “a backwards move,” reinforcing its value as a critical component of their contamination control process.

“The Dycem mats work very well, are user friendly, and overall has been very positive.” – Steve Hedges, Continuous Improvement Manager

ABOUT R.W. SIMON

Founded in 1958, R.W. Simon has established itself as a trusted name in both plastics and ventilation manufacturing. The company combines technical expertise with responsive customer service, delivering high-quality, custom-engineered products from its state-of-the-art facility in Torrington. Whether developing precision thermoplastics or innovating in solar shading and ventilation, R.W. Simon remains committed to performance, sustainability, and quality.