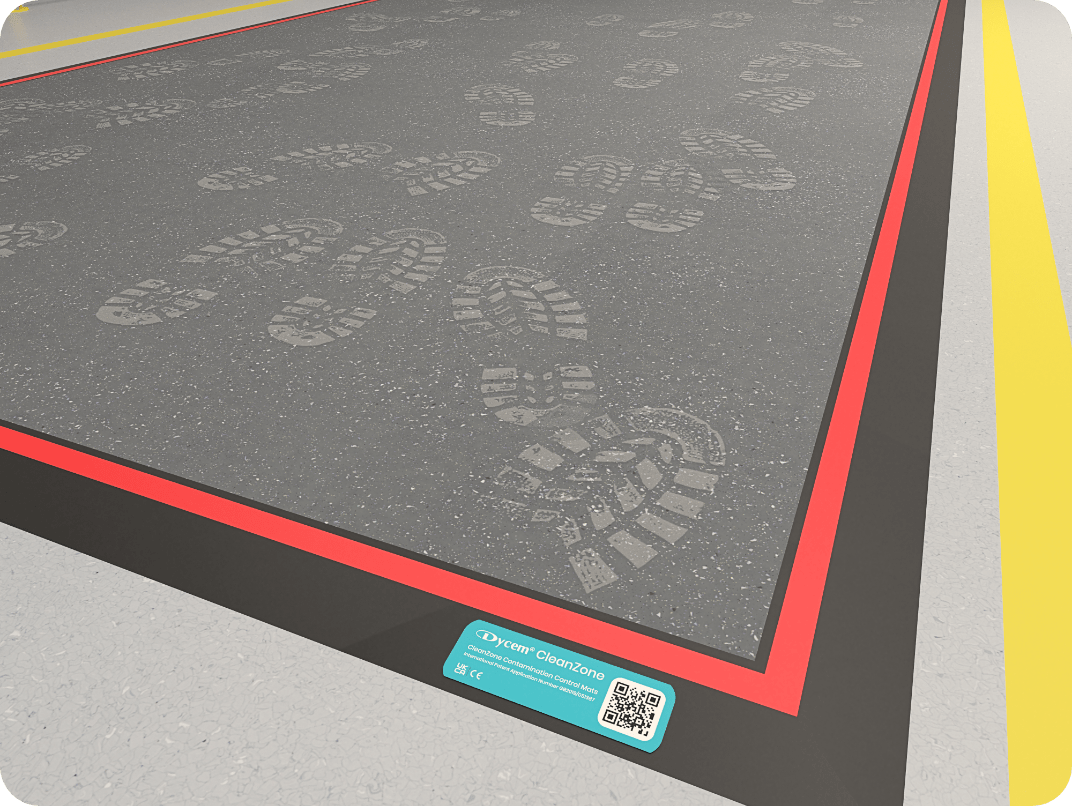

Dycem® Floating Mats

Loose-laid Contamination Control Mats

Loose-laid and movable

Prevents up to 99.9% of

floor-level contamination

3+ year

average lifespan

Easy to set up, move, and clean

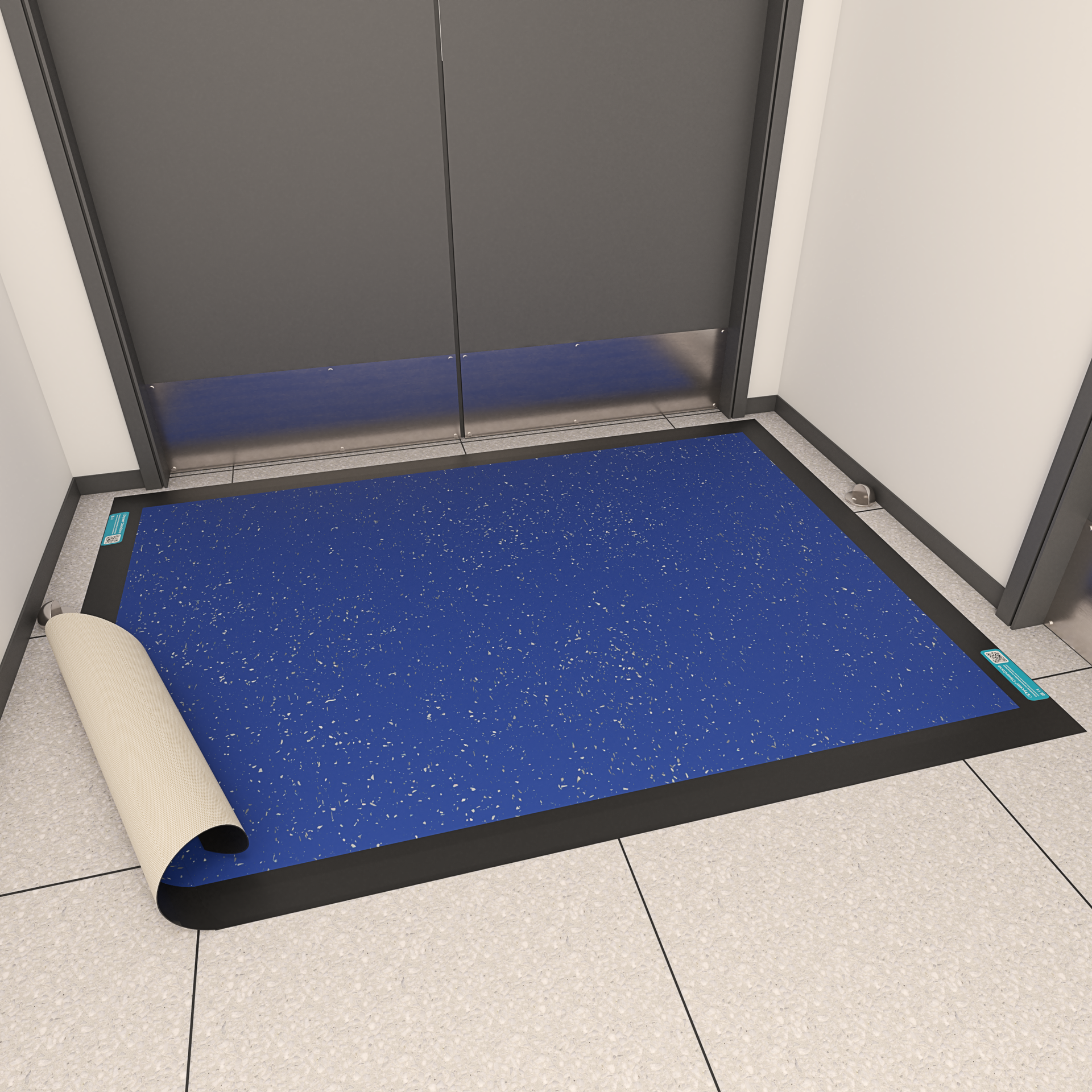

Dycem’s Floating Mats are loose-laid, ready-to-use mats that offer the same great benefits as our Dycem CleanZone product, but without the need for permanent installation. These contamination control mats are versatile and can be easily moved, making them suitable for locations where permanent installation to the subfloor is not possible. Dycem Floating Mats are ideal for facilities with raised flooring, access tiles, or areas under construction.

Dycem Floating Mats have a surface resistivity of 10⁸ ohms, making them static dissipative. Their natural tack traps and retains particulates from shoes and wheels, while the surface energy (van der Waals forces) of the Dycem material draws additional particulate out of the air.

Attracts, captures, and retains up to

99.9%

of particulate.

Ready to get started?

Contact our team today.

Why Floating Mats?

For quality managers and facilities professionals, contamination control in non-permanent flooring areas presents unique challenges. Traditional solutions like sticky mats, shoe covers, and foot baths often fall short, creating compliance risks, ongoing replacement costs, and unnecessary waste.

Dycem Floating Mats deliver the same proven polymeric technology as our permanent systems, meeting stringent regulatory standards while offering complete flexibility in placement. They can be repositioned or removed with ease, making them ideal for leased spaces, temporary zones, and high-traffic pathways.f

Read more

With a 3+ year lifespan and minimal maintenance requirements, Dycem floating mats delivers significant cost savings over its lifespan compared to disposable alternatives, while inhibiting the growth of microbes and supporting your facility’s sustainability goals.

Whether you manage a pharmaceutical cleanroom, medical device manufacturing facility, or electronics production environment, Dycem mats offers a proven, sustainable

How Dycem Floating Mats work

Floating Mats feature Dycem’s naturally tacky surface, which attracts, captures, and retains up to 99.9% of foot- and wheel-borne contaminants on contact. Using Van der Waals forces, microscopic electromagnetic interactions, contaminants are secured to the surface until the mat is cleaned.

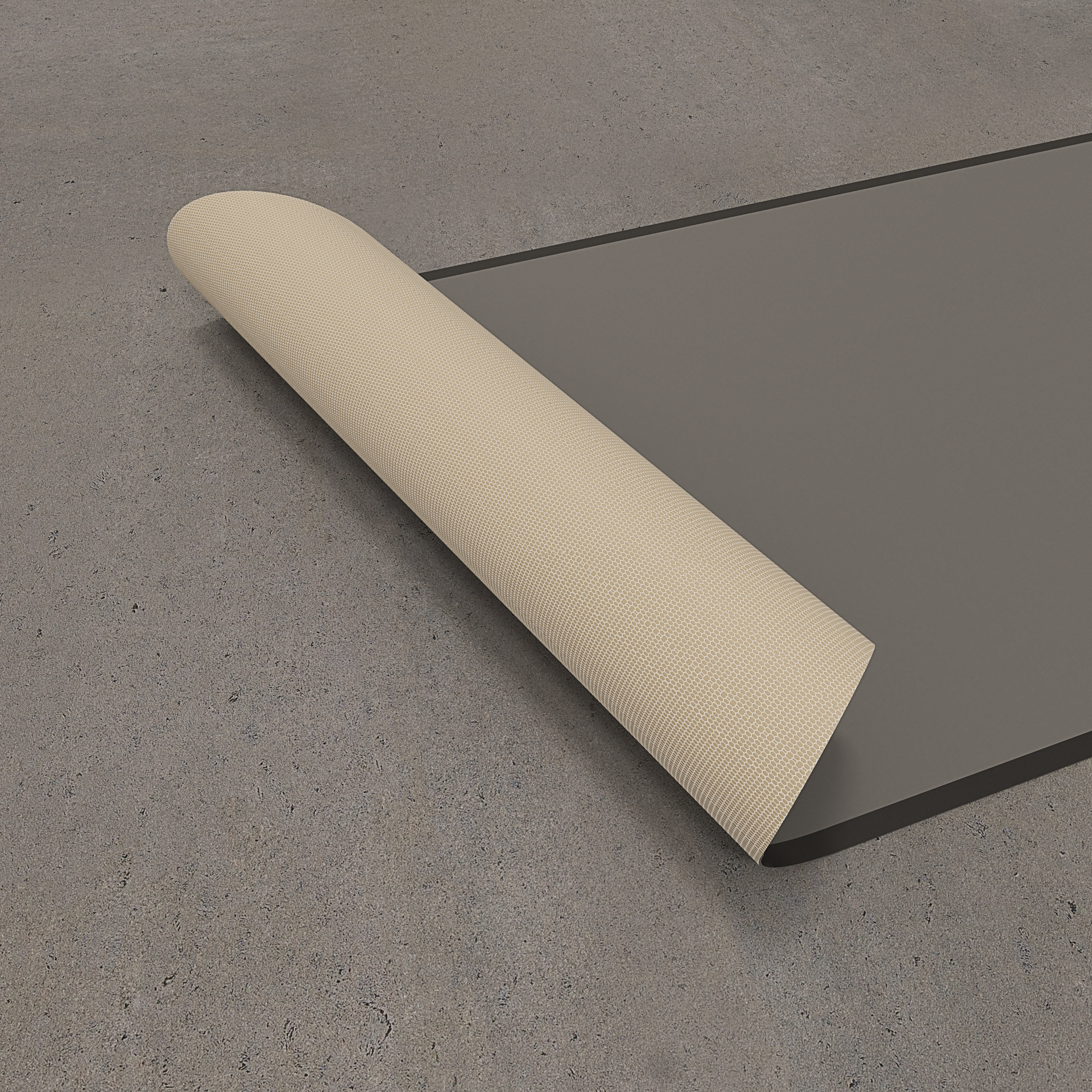

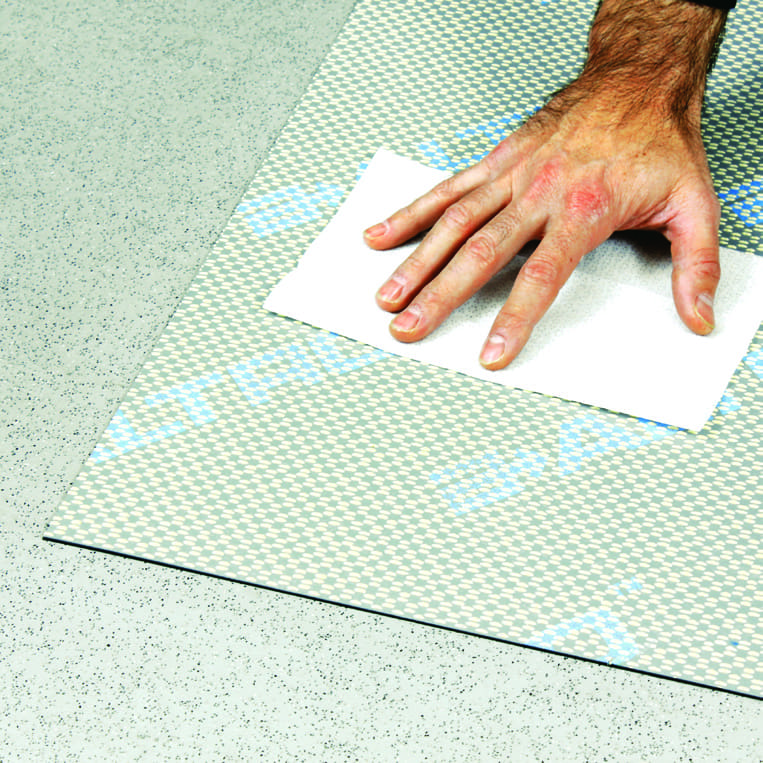

Unlike disposable sticky mats, Floating Mats maintain their performance even with repeated overstrikes in the same spot. Their non-adhesive base allows them to be placed, repositioned, and removed easily, making them ideal for areas where permanent installation isn’t possible.

Operating with a forklift? Click here to explore Dycem’s heavy-duty WorkZone mats.

Read more

Suitable for shoes and light-wheeled traffic, CleanZone integrates easily into your existing contamination control strategy. Engineered for up to 99% contamination control, CleanZone has been proven through scientific testing and real-world applications to deliver superior decontamination in just six footfalls or three full-wheel rotations. With a weight tolerance of up to 1000 lbs/in² (70 kg/cm²) and a durable lifespan of over three years, CleanZone ensures consistent, dependable protection in high-traffic areas.

Built-in antimicrobial protection

Every Dycem mat incorporates Biomaster, a silver ion-based antimicrobial technology that actively inhibits microbial growth by up to 99.9%. This protection remains effective for the life of the product, ensuring a continuous defence at floor level against microbial contamination in cleanrooms and controlled environments.

Tips for use

- Keep the area where Dycem Floating mats are placed clear and free from obstacles such as bins, crates, carts, or racks.

- Ensure no heavy items or equipment are left on the Dycem surface for prolonged periods of time.

- During usage, your Dycem Floating mats may look dirty. This is good and shows that the product is working to keep contamination out of your critical environments.

- Slight scuffing may appear if shoes frequently drag across the Dycem mat in high-traffic areas, however, this does not affect performance.

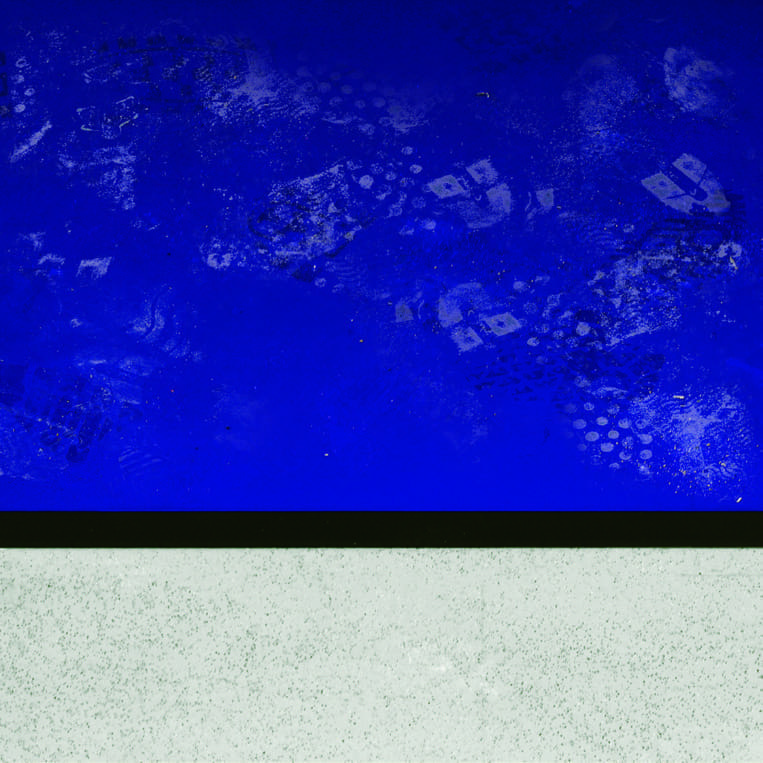

- Floating Mats are not adhered to the subfloor, cleaning underneath is required for optimal contamination control.

Our ISO-certified processes ensure consistent quality, resulting in high-quality contamination control mats that deliver long-term performance. Dycem’s manufacturing meets EN 150 9001 and 14001 standards, California Proposition 65 and EU REACH compliance, ensuring the highest quality and environmental responsibility.

Strategic implementation for floating mats

Placing Dycem Floating Mats in the right locations ensures maximum protection for your controlled environment. These mats are designed to work seamlessly within your contamination control strategy, capturing up to 99.9% of foot- and wheel-borne particles before they can spread.

Common installation points include:

Non-permanent flooring areas

Near critical products and processes

Gowning rooms

Air showers

Storage and packaging entry/exit points

Customization options

Every facility is unique and the Dycem team works with you to find the best solution. Floating mats can be tailored to meet your specific needs through:

Color options to match facility aesthetics

Cobalt

Green

Titanium

Red

Midnight

Slate

Edge finishing options for easy integration

Traffic safety visuals

The benefits at a glance

Vinyl Membrane Backing

The mats are adhered to a moisture-resistant backing that aids in maintaining rigidity for the product life.

Ready To Use

Dycem Floating Mats are pre-assembled and shipped directly to the customer for immediate placement and use.

Antimicrobial Protection

Biomaster silver-ion technology inhibits microbial growth by up to 99.9% throughout product life.

Minimal Downtime

Simply lay your floating mat in the unavoidable flow of traffic and personnel can simply walk across to decontaminate shoes.

Static Dissipative

Surface resistivity of 10⁸ ohms, reducing electrostatic discharge (ESD) concerns.

Responsbility Manufactured

Manufactured to ISO 9001/14001 standards, and fully compliant with Cal Prop 65 and REACH.

How to clean Dycem® Floating Mats

Learn how to properly clean your floating Dycem contamination control mat for optimal performance. This video demonstrates the best practices for daily cleaning and care using the recommended tools and techniques.

Cleaning Instructions for Floating Mats

1.Clean Dycem mats once per day, or after each shift in high-traffic areas, to ensure optimal performance. Always use a Dycem-approved cleaning solution to maintain the mat’s effectiveness.

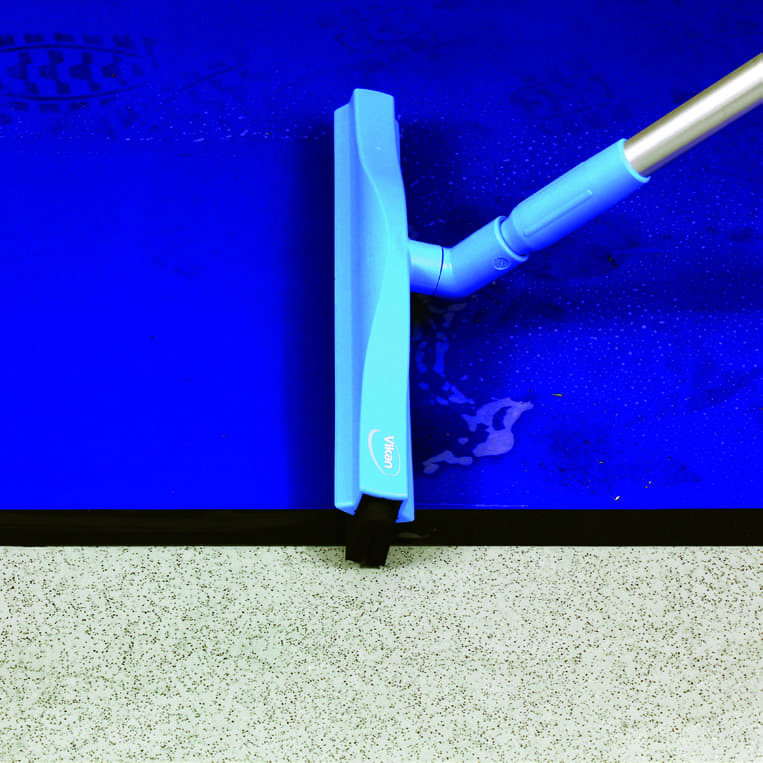

2. Clean the subfloor, agitating with a hard foam squeegee (such as Vikan) in a vertical direction, and remove excess residue/liquid. Repeat horizontally.

3. Clean the underside of the Dycem mat using an isopropyl alcohol wipe (70/30 IPA recommended) and allow it to dry.

4. Replace the Dycem mat on the subfloor. Using a spray bottle, mop, or pre-saturated wipe, apply the diluted cleaner to the entire mat ensuring complete coverage.

5. Using a squeegee system, such as a Vikan, agitate the surface of the mat lifting the retained particulates. Working from closest to the controlled area moving outwards, agitate in both a vertical and horizontal direction for maximum contamination removal.

6. Pull the dirty liquid to the edge of the mat surface using the squeegee. Collect with a sponge, mop, or cloth and dispose per facility mandated SOP’s. For heavily saturated mats, repeat cleaning steps 1-6 until the liquid removed is visibly clear. Allow the mat to dry before use.