Dycem® vs Footbaths & Sanitizing Mats

Goods manufacturing practices, personal hygiene policies and HACCP procedures are the foundation of many safety and quality assurance programs, specifically within food and beverage processing and manufacturing facilities. These programs aim to prevent pathogens from contaminating the facility and products. They use footbaths filled with a liquid sanitizing solution or mats containing a sanitizing powder, often used to decontaminate footwear before production. While common, these methods have many factors that should be evaluated.

Control of Microbes

Footbaths and sanitizing mats rely on chemical disinfectants to effectively decontaminate. In addition to this, physical cleaning is necessary to remove debris and other visible dirt from the soles of shoes. Personnel must allow enough contact time for the disinfectants to work to their potential. If too much organic material builds up in the container, sanitizers may become less effective.

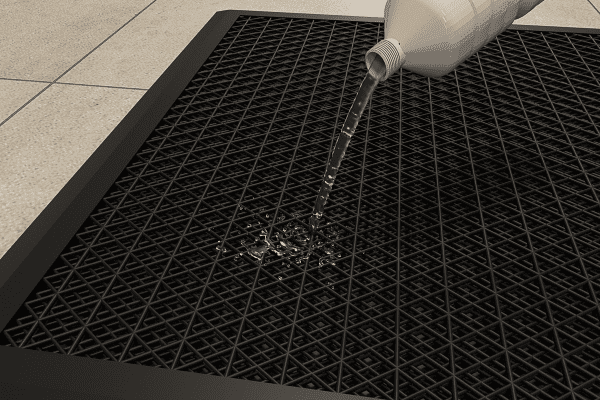

However, Dycem mats capture and retain all particulate matter that comes in contact with the surface, whether viable or non-viable. While the particles are kept on the mat, the Biomaster silver additive restricts any additional growth of potentially harmful microbes.

Health & Safety

If not maintained or used correctly, footbaths and sanitizing mats can cause more harm than good. Footbaths left uncleaned or unmonitored can become a “bacteria bath”, introducing potentially harmful microbial growth. Additionally, if concentration levels of chemicals are not kept to certain specifications, the risk of viable particles remaining on shoes is heightened. These same chemicals can also erode the soles of shoes when shoe covers aren’t worn, posing the risk of contaminated objects from footwear entering the production environment.

Dycem mats are effective even when dirty. Between cleanings, the polymeric composition attracts and retains dirt and debris, while the Biomaster additive provides 24/7 protection against microbial growth. Customized for each specific facility, Dycem’s mats also prevent contamination from moving between hygiene levels and work zones.

Know the facts...

Currently using an alternative to Dycem?

Make sure you understand the risks of common contamination control solutions. Download our comparison brochure to learn more!

Cross-Contamination

Foot baths are primarily employed in food and beverage facilities to prevent cross-contamination among products. This is especially crucial when workers move between production spaces, potentially carrying over contaminants like allergens. However, after the initial use, the effectiveness of the antimicrobial solution diminishes. As more workers pass through, the solution becomes less effective, necessitating the disposal of the old solution and the addition of a fresh mix. Cross-contamination from footwear can originate both inside and outside the processing plant, underscoring the necessity of a footwear sanitation program in all facilities. Implementing such a program can be facilitated with the assistance and training of a food safety specialist.

Dycem mats provide an effective solution, even when soiled. Between cleanings, the composition of the mats attracts and retains dirt and debris, while the Biomaster additive ensures round-the-clock protection against microbial growth.

Employee Downtime

Maintaining footbaths and sanitizing mats can be quite a process that involves many steps. Monitoring, replenishing, cleaning, and disposing contaminated liquids or powders requires frequent attention from operators or janitorial staff. Frequent ordering and stocking of chemicals can also be a time-consuming task. Extended contact time for effective decontamination and multi-step processes causes a bottleneck for operators and creates unproductive downtime.

Placed in the unavoidable traffic flow, operators must walk over the Dycem mats as part of their regular entry or exit procedures. Maintenance is minimal for the lifespan of the mats, which is 3+ years on average. There are no chemicals or solutions that must be kept on hand. Once installed, Dycem mats are easily incorporated into the daily wet cleaning schedule.

Total Cost

The upfront purchase and installation costs of footbaths, sanitising mats, and the ongoing price of stocking the chemicals and solutions required can add up quickly, especially for larger facilities with higher volumes of people and production. The hidden costs of employee downtime for use and maintenance, potential health and safety claims, and the risk of recalls or rejected batches from contamination cannot be ignored.

With a lifespan of 3+ years, minimal downtime for use and maintenance, and, most importantly, the reduction of high-priced contamination issues, Dycem mats provide a superior return on investment and are the most efficient total-cost solution.