Dycem® WorkZone

Heavy-Duty Contamination Control Mats

Suitable for

heavy wheels

Captures up to 99.9% of

floor-level contamination

3-5 year

average lifespan

Proven contamination control for heavy-duty environments

In industrial and warehouse environments, maintaining contamination control presents unique challenges. Heavy wheeled traffic and constant material movement create significant contamination risks, yet traditional control methods like sticky mats fail under these demanding conditions. Most facilities rely on inadequate solutions that compromise safety, efficiency, and ultimately, product quality.

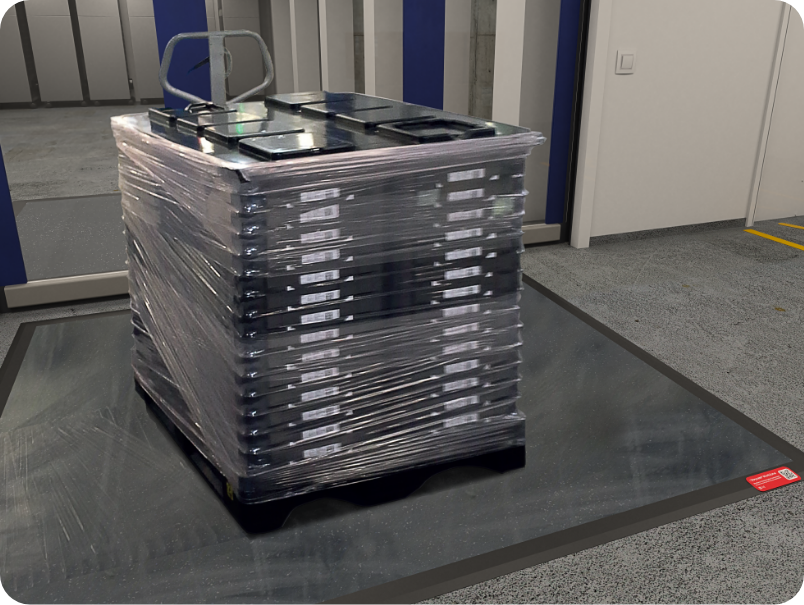

Dycem WorkZone is an industrial-grade contamination control system engineered for heavy-duty environments. Capable of supporting forklifts, pallet jacks and loads up to 1,280 lb/in² (90 kg/cm²), WorkZone captures up to 99.9% of wheel-borne contamination before it enters your critical areas.

Attracts, captures, and retains up to

99.9%

of particulate.

Ready to get started?

Contact the Dycem team today.

Why WorkZone?

For facility and warehouse managers, contamination control strategies (CCS) aren’t just about compliance – they’re about protecting product integrity while maintaining a high level of operational efficiency.

Traditional methods like sticky mats fail under heavy wheeled traffic such as pallet trucks, forklifts, and trolleys, creating safety hazards, workflow disruptions and the risk of contamination entering critical areas.

Read more

Effective risk management in industrial environments demands robust monitoring and controls, particularly where multiple production processes create diverse sources of contamination. Your operations are too important to leave contamination control to chance. WorkZone provides comprehensive protection against various contaminants, including foot and wheel-borne, supporting your facilities and equipment with reliable, long-term performance.

WorkZone is specifically engineered for industrial environments where material handling equipment operates continuously with high traffic volumes. Our polymeric technology offers proven contamination control that is compatible with heavy-wheeled traffic. WorkZone includes optional food-grade stainless steel edging, ensuring a smooth transition for wheeled traffic.

With minimal maintenance requirements and a 3+ year lifespan in high-traffic areas, WorkZone delivers significant long-term cost savings while supporting your facility’s regulatory compliance and sustainability goals.

How does WorkZone work?

WorkZone uses advanced polymeric technology, specifically designed for heavy-duty environments, to provide a naturally tacky surface that effectively attracts, captures, and retains contaminants upon contact. By leveraging Van der Waals forces, the electromagnetic interactions secure the contaminants firmly onto the mat’s surface, ensuring they remain trapped until the mat is cleaned.

Read more

Unlike traditional sticky mats, WorkZone maintains its performance even under repeated foot traffic or wheel rotations in high-use areas, ensuring consistent contamination control over time.

With a durable, low-profile design tailored for heavy-wheeled traffic, WorkZone integrates easily into your contamination control strategy. Engineered for up to 99.9% contamination control, WorkZone achieves optimal decontamination in three full-wheel rotations. Designed to support forklifts and weight tolerances of up to 1280 lbs/in² (90 kg/cm²), WorkZone provides long-term protection with a lifespan of 3+ years, ensuring contamination control even in demanding industrial environments.

Built-in antimicrobial protection

Every WorkZone mat incorporates Biomaster, a silver ion-based antimicrobial technology that actively inhibits microbial growth by up to 99.9%. This protection remains effective for the life of the mat even through heavy traffic conditions, providing continuous defence against microbial contamination in cleanrooms and controlled environments.

Technical excellence

WorkZone sets the standard for contamination control with its innovative design and Dycem’s unmatched technical expertise. With a surface resistivity of 10⁸ ohms, WorkZone effectively dissipates static discharge whilst maintaining superior particle retention in industrial settings.

For added assurance, every Dycem product includes coverage for our annual particle collection efficiency test (PCET). This service provides documented evidence of WorkZone’s ongoing effectiveness, supporting your quality assurance records and ensuring continuous, reliable contamination control.

Our ISO-certified processes ensure consistent quality, resulting in high-quality contamination control mats that deliver long-term performance. Dycem’s manufacturing meets EN ISO 9001 and 14001 standards, California Proposition 65 and EU REACH compliance, ensuring the highest quality and environmental responsibility.

Strategic implementation

Optimal placement maximizes WorkZone’s effectiveness in your contamination control strategy, and the Dycem team can support and advise on best practices. WorkZone offers various placement options to prevent contamination from entering your facility.

Common installation points include:

Goods-in & material entrances and exits to controlled areas

Inside airlocks (MALs), and product transfer areas

In hallways or thresholds between different product lines or processes

Layered between ISO levels or barrier zones

Customization options

Every facility is unique and the Dycem team works with you to find the best solution. Custom sizes and shapes for complex layouts available. WorkZone can be tailored to meet your specific needs through:

Color options to match facility aesthetics

Granite

Charcoal

Edge finishing options for easy integration

Traffic safety visuals

The benefits at a glance

Easy Maintenance & Washing

Cleaning integrates seamlessly with existing SOPs, offering optimal performance even under heavy use.

Superior Contamination Control

Captures up to 99.9% of floor-level and 75% of airborne particulates with proven retention.

Antimicrobial Protection

Biomaster silver-ion technology inhibits microbial growth by up to 99.9% throughout product life.

Long Lifespan

Delivers performance for 3-5 years, outperforming disposable alternatives in value and sustainability.

Customizable Design

Tailored shape and size to your facility layout and traffic flow.

Static Dissipative

provides reliable protection against electrostatic discharge (ESD) risks with 10⁸ ohms surface resistivity

Secure Installation

Low-profile edging enables smooth wheel transitions up to 1280 lb/in² (90 kg/cm²), professionally installed on to the subfloor for optimal stability.

Operational Efficiency

Continuous contamination control without disrupting workflow or requiring frequent maintenance stops.

Quality Assured

Manufactured to ISO 9001/14001 standards, and fully compliant with Cal Prop 65 and REACH.

With over five decades of contamination control expertise, WorkZone represents the ONLY proven solution for heavy-duty industrial applications. Our industrial facility contamination control mats deliver superior performance, durability, antimicrobial protection and long-term cost efficiency compared to traditional methods, such as sticky mats, shoe covers and foot baths.