Dycem® vs Sticky Mats

Sticky mats, also known as “tacky mats,” are disposable, adhesive-based products used for floor-level contamination control. However, scientific testing shows that sticky mats are only 27% effective in preventing contamination from foot and wheel traffic. In contrast, Dycem’s reusable contamination control mats offer superior performance, making them a more reliable and sustainable option. When choosing between the two, it’s essential to consider factors like effectiveness, durability, and environmental impact.

Size

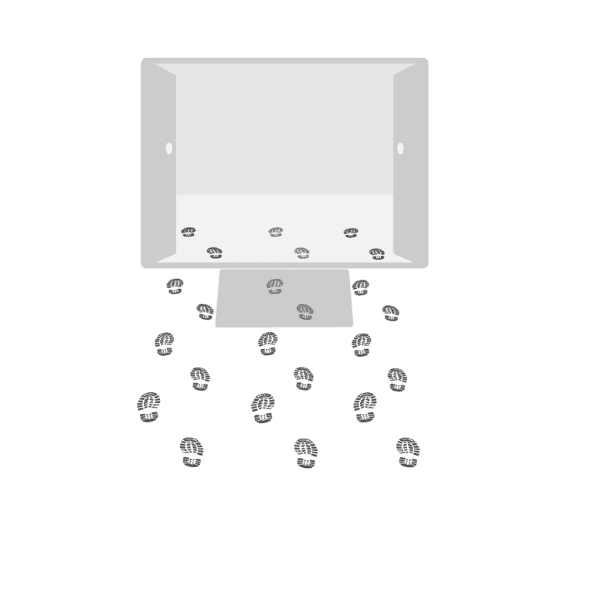

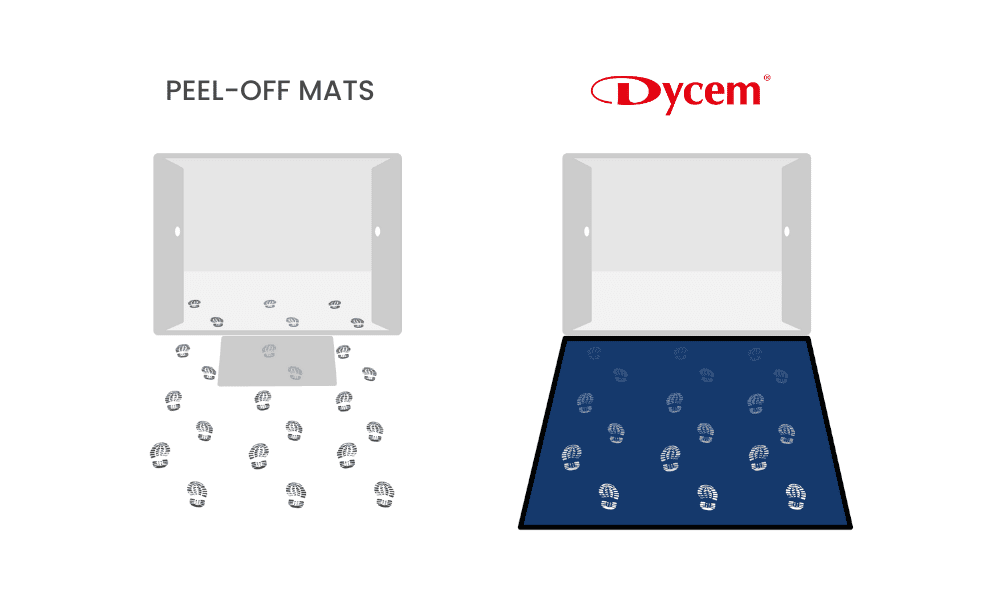

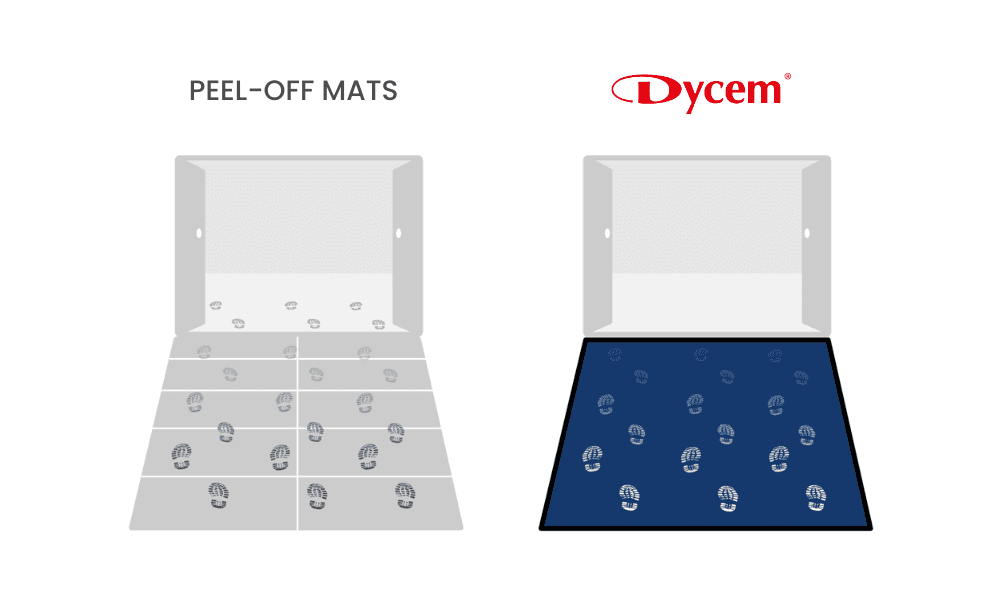

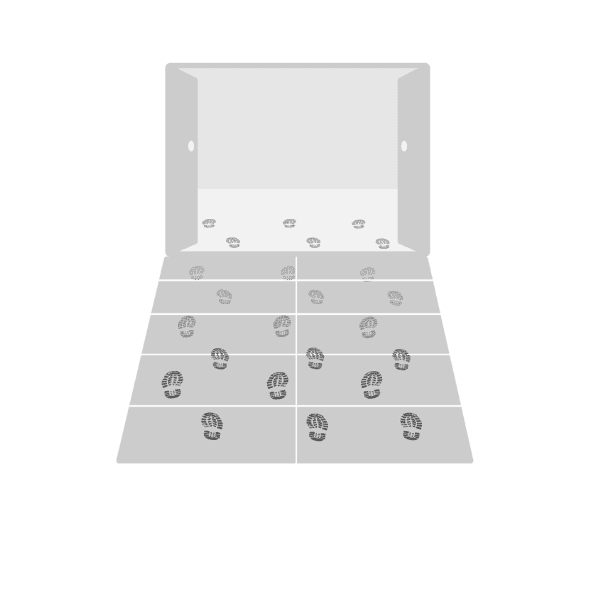

Sticky mats typically measure around 3 feet by 2 feet (1 meter by 0.5 meters), which is not sufficient to effectively decontaminate shoes and wheels. Research shows that optimal decontamination requires at least six footfalls and three full wheel rotations. The small size of sticky mats can lead to personnel stepping over or around them, resulting in inadequate contamination removal.

Dycem contamination control mats are customizable to create an unavoidable barrier, ensuring maximum protection and effective decontamination every time.

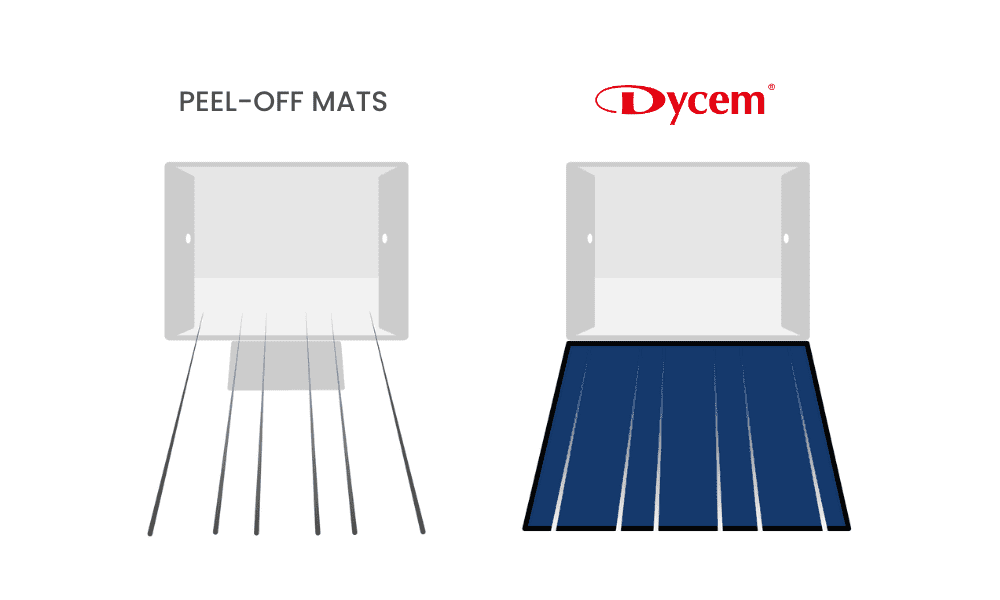

Ganging

Some facilities attempt to overcome the size limitations of sticky mats by “ganging” multiple mats together. To achieve 80% contamination prevention, at least 10 sticky mats must be used, peeled twice per 8-hour shift. This approach is costly, labor-intensive, and generates significant waste, while also failing to address issues like material, labor, storage, and disposal costs. Contamination can also collect in gaps between mats.

Dycem mats offer a seamless, more effective solution with up to 99.9% effectiveness and built-in antimicrobial protection.

Know the facts...

Currently using an alternative to Dycem?

Make sure you understand the risks of common contamination control solutions. Download our comparison brochure to learn more!

Build Up

Sticky mats lose effectiveness as contaminants build up with repeated steps, potentially transferring particles back onto footwear and spreading them to other areas. This issue is exacerbated by the small size of sticky mats. Research shows that Dycem mats remove up to 99% more particles than sticky mats, which can introduce 9.6% to 381.9% more contaminants, even with already contaminated footwear. Choosing the right mat, like Dycem, is crucial for maintaining a clean and safe environment.

Wheeled Traffic

Sticky mats struggle with wheeled traffic, often wrapping around wheels, tearing, and transferring adhesive into critical environments. They quickly become saturated, reducing effectiveness in heavy-wheeled traffic areas where larger particles are prevalent.

Dycem WorkZone mats are specifically engineered to handle heavy-wheeled traffic, supporting up to 1280 lb/in² (90 kg/cm²). For added protection, Dycem offers a food-grade stainless steel border to prevent damage from heavy-wheeled traffic entering and exiting the mat.

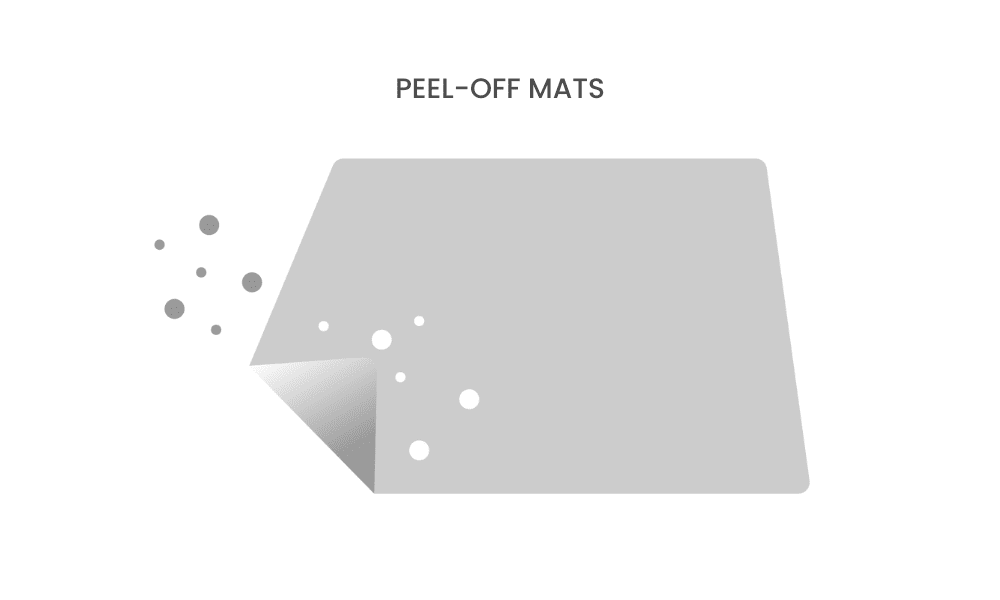

Particle Shedding

An independent study by a sticky mat manufacturer revealed that removing a used sticky mat can release an average of 125,000 particles back into the environment, re-contaminating the area.

Dycem mats capture up to 99.9% of contamination, and their high surface energy ensures that particles are securely retained until they are washed away, preventing re-dispersal into your controlled environment.

Cost

While sticky mats may seem less expensive upfront, their frequent replacement, disposal, and associated risks make them more costly over time.

Dycem mats, with a lifespan of 3-5 years, offer a more cost-effective solution. A recent analysis by an semiconductor industry customer showed an approximate $300,000 savings over 5 years with Dycem compared to sticky mats.

Waste

Sticky mats generate large amounts of contaminated waste, requiring costly specialized disposal. Each layer removed forms an 8-inch (20 cm) ball of waste, filling multiple dumpsters annually.

Dycem’s reusable mats significantly reduce waste and disposal costs, providing a more sustainable and cost-efficient contamination control solution.

Ganged Sticky Mats

20% of contamination enters the

critical environment

Dycem vs Sticky Mats

<0.01% of contamination enters the

critical environment