Cleanrooms

Dycem is engineered specifically for cleanrooms, supporting environments from ISO Class 9 to ISO Class 2. Our goal is to raise the bar for cleanliness and contamination control in these critical spaces. With tacky properties that capture contaminants from feet and wheels, and a natural static charge that pulls airborne particles to the surface, Dycem operates on two levels of protection. Easy to clean and maintain within existing protocols, Dycem mats offer a long-lasting, reliable solution for contamination control in cleanrooms.

Where to use Dycem in Cleanrooms

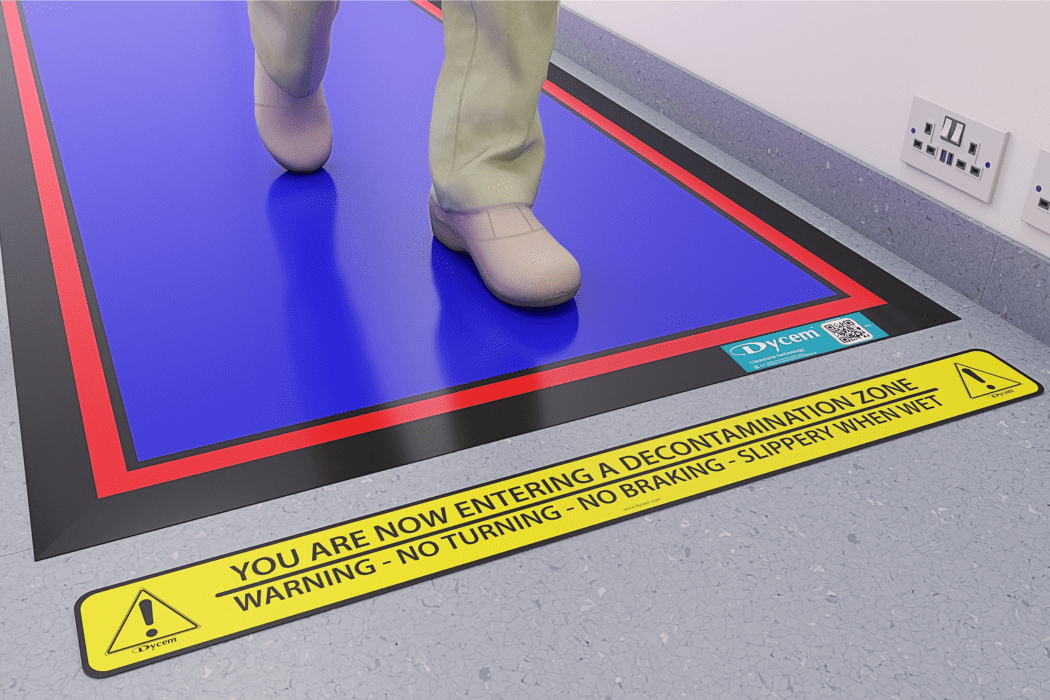

Entry and Exit to Cleanrooms

Inside airlocks, gowning rooms, and air showers

In hallways between products and processes

Adjacent to critical products and processes

Contamination: The Risk in Cleanrooms

Cleanrooms are crucial for controlling particles to ensure quality, safety, and profitability. Contamination from personnel, products, or airflow can disrupt processes and spread microorganisms rapidly.

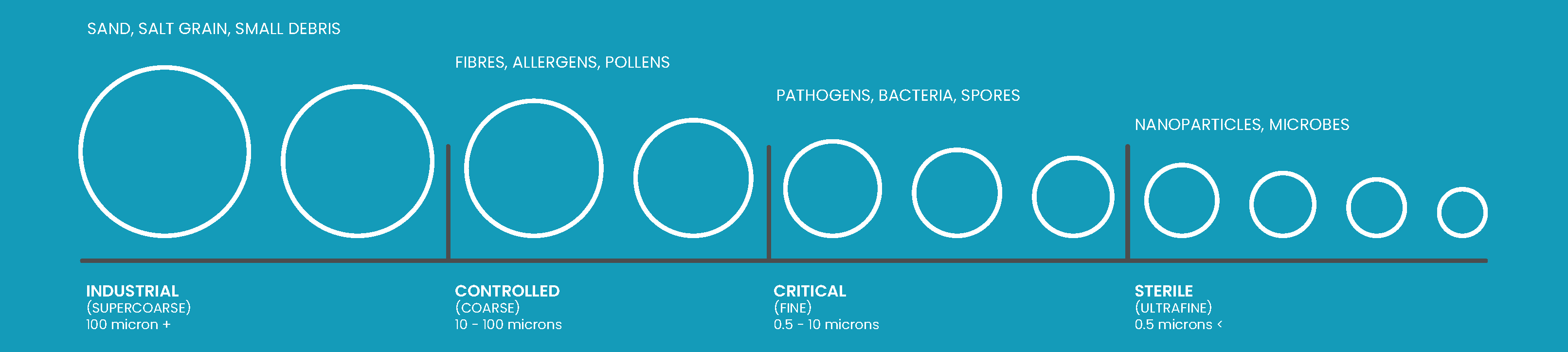

Common contaminants include visible particles like dust and fibers, and invisible ones like microbes and allergens. Static (ESD) can also damage electronic components.

The presence of these contaminants can lead to reduced product quality, factory shutdowns, unsatisfactory audits, product recalls, and health risks.

An effective contamination control strategy, including Dycem mats, is essential for maintaining cleanroom operations.

Don't Ignore the Floor...

80% of Contamination Enters a Critical Space at Floor Level.

Benefits of Dycem in Cleanrooms

superior floor & Air particulate control

Dirt and dust are captured on Dycem mats and remain on the surface until cleaned off. With Dycem’s flooring for cleanroom, benefit from a reduction in floor-level particulate of up to 99.9% and a reduction in air particulate levels of up to 75%.

REDUCED MICROBIAL CONTAMINATION CONCERNS

With Dycem mats installed prior to critical areas, our cleanroom customers have peace of mind that damage from microbial contamination is minimized. All Dycem products contain Biomaster, an active antimicrobial additive.

COST-EFFECTIVE, SUSTAINABLE ALTERNATIVE

Unlike disposable contamination control solutions, Dycem mats last on average 3+ years. Cleanroom facilities typically see an ROI shortly after purchase, as well as the added benefit of a reduced carbon footprint due to less plastic waste.

Our Products, Your Industry

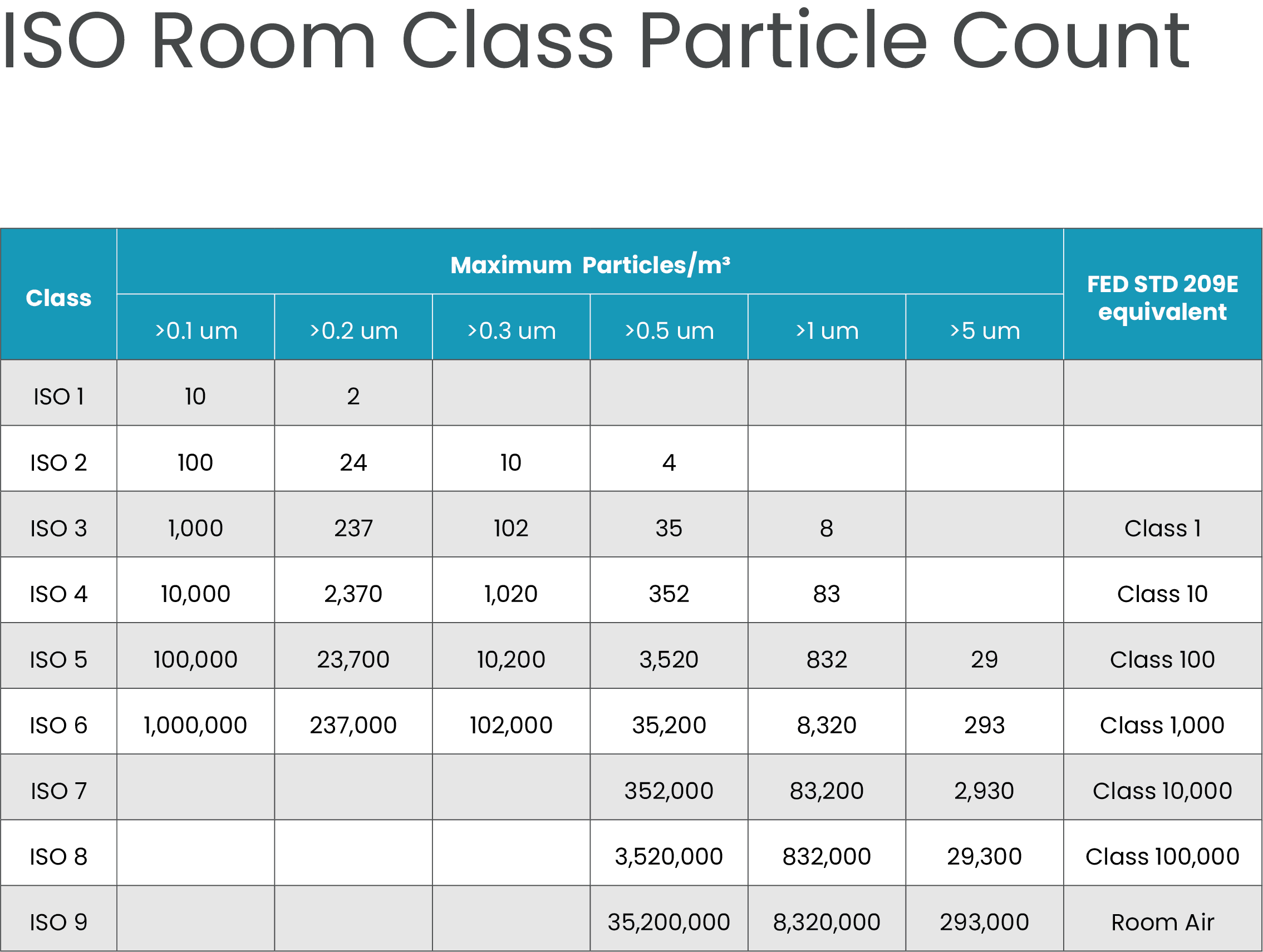

Cleanrooms must adhere to strict protocols and processes to reach industry standards and their relevant ISO level. Dycem has a range of highly effective flooring for cleanroom solutions to support achieving these standards. Keeping contamination out of cleanrooms is our priority.

Dycem CleanZone

CleanZone helps control contamination from the shoes of personnel.

Dycem Floating Mats

Floating Mats are a contamination control solution that can be moved as needed.

In Your Industry

Discover your industry’s specific applications—all conveniently summarized right here.

Success Stories...

Discover our success stories in your industry.

Learn how our customers have benefitted from installing Dycem.

Contamination in Cleanrooms

The ISO particle count system is a standardized method for quantifying and categorizing airborne particle concentrations in controlled environments.

It adheres to ISO guidelines and is vital for quality control in industries like pharmaceuticals and electronics manufacturing.

The Visible and Invisible Risk to Your Cleanroom