Welcome, fellow guardians of controlled environments! If you find yourself obsessing over the tiniest particles and dreaming of a contamination-free environment, you’re in the right place. Here are six niche steps to prevent contamination and improve contamination control.

Step 1: Embrace the Particle-Size Obsession

Contamination often goes unnoticed, but with the emergence of new technology, it’s time to be a detective for particulate sizes. Invest in advanced particle counters that not only identify particle contamination but also categorize them by size. Understanding the size distribution allows you to tailor your contamination control strategies to address even the smallest culprits.

Step 2: Airflow Mastery

Imagine your controlled environment as a choreographed dance, with particles moving gracefully in a well-orchestrated routine through points called vectors. To achieve this, optimize your airflow distribution and contamination control. Utilize computational fluid dynamics (CFD) simulations to visualize and tweak airflows, ensuring filtration and that particles are not lingering where they shouldn’t be.

Step 3: UV-C Disinfection

Introduce the power of UV-C light into your contamination control arsenal. UV-C light is a formidable foe against microorganisms and is also safe, non-toxic and can be angled for a directed sweep to decontaminate across numerous hard-to-reach surfaces. Install UV-C lamps strategically in hard-to-reach corners and critical zones to obliterate any lingering threats. It’s like having a silent superhero patrolling your controlled environment.

Step 4: Particle-Repellent Attire – Suit Up for Success

Your personnel can inadvertently introduce a risk of contamination, so let’s armor them up. Invest in state-of-the-art contamination-repellent attire, like contamination gowning and shoe covers. Picture suits with nanotechnology coatings that repel particles like a force field. Make it a fashion statement that says, “Contamination, you shall not pass!”

Step 5: RFID Tagging for Equipment Hygiene

Equip your tools and equipment with Radio Frequency Identification (RFID) tags to track their hygiene status, as they are sources of contamination. Develop a system where each item undergoes regular decontamination, and the RFID tag updates its status accordingly. This ensures that your tools are as clean as a whistle and ready for action when duty calls.

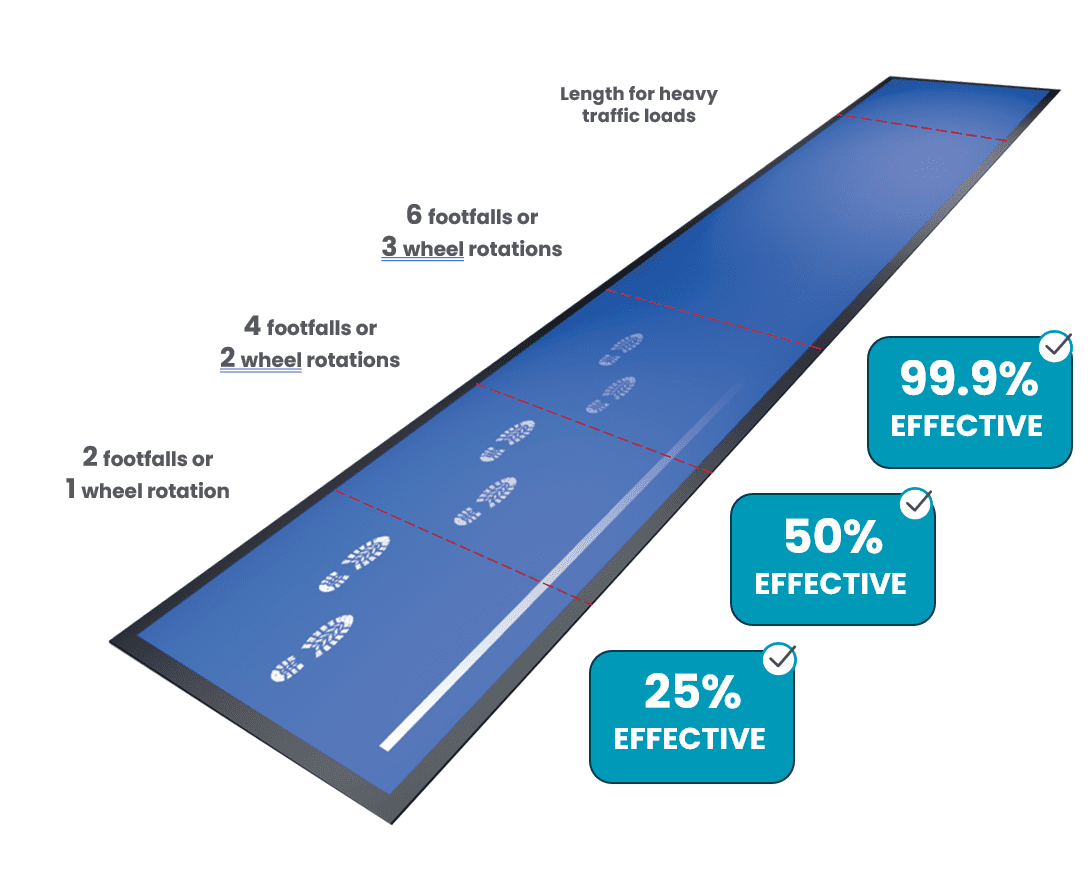

Step 6: Dycem Magic

Dycem contamination control helps in maintaining a pristine cleanroom environment. Dycem mats are strategically positioned at entry points to capture and retain particles from shoes and equipment wheels. Regular cleaning ensures the effectiveness of Dycem in reducing both airborne and surface contaminants. This integrated approach adds an extra layer of protection, reinforcing the commitment to upholding the highest standards of cleanliness within the cleanroom facility. So, roll out the Dycem products carpet and let the magic unfold in the fight against contamination!

Choose Dycem for Improved Contamination Control

Embrace the details, maintain cleanliness, and enjoy a pristine, contamination-free space. Your customers will appreciate it, and your facility will remain safe.

Contact us today to improve your contamination control. Dycem supports good manufacturing practices and contamination monitoring for the safety of your products, staff, and customers, regardless of your industry.