Establishing a Contamination Control Strategy (CCS) within cleanrooms or controlled environments is fundamental for safeguarding a company’s reputation, increasing profitability, and maintaining health and safety standards.

The first step in developing a CCS involves understanding the range of contamination risks. Among these, floor-level contamination is a concern you shouldn’t ignore, as research has shown that 80% of contamination enters via the floor level. Neglecting this aspect could compromise the effectiveness of the CCS, making sure to implement proactive contamination control methods to mitigate floor-level risks, such as preventing the entry of contaminants via the footwear soles.

Shoe Covers

Many industries use shoe covers as a preventive measure to protect cleanrooms or controlled environments from the contamination that can be present on personnel footwear. Shoe covers are slip-on garments designed to fit over the shoe’s sole and prevent the shoe from touching the floor, reducing the contamination risk.

| Pros | Cons |

| Low-cost

One size fits all |

Single-use

Easily damaged Application can cause cross-contamination Particulates can shed into the cleanroom |

Pros

- Initial Low-Cost: Shoe covers are a relatively low-cost option for managing floor-level contamination, especially compared to alternatives such as implementing more extensive cleaning protocols.

- Versatile: They are designed to fit various shoe styles and sizes, making them accessible and practical for a wide range of personnel.

Cons

- Waste: Most shoe covers are made of disposable plastic and are designed for single use. Users must dispose of them and apply a new pair each time they exit and re-enter the cleanroom or controlled environment, which could be many times a day.

- Fragile Material: Shoe covers are crafted from plastic, intended to provide minimal coverage for shoes, and the thin material is susceptible to tearing. Positioned at the sole of the shoe, a tear in the cover may easily go unnoticed, posing a significant risk of contamination as individuals may inadvertently track dirt into clean areas.

- Cross-Contamination: Using your hands to physically apply the shoe cover can transfer contamination from your hands onto the outside of the shoe cover, presenting a risk. Depending on the material they are made from, low-quality shoe covers may shed particulate matter that your personnel could track into the cleanroom or controlled environment.

Sticky Mats

The most common approach to floor-level contamination control is adhesive-based sticky mats, also known as “tacky mats,” “peel-off mats,” or “disposable floor mats.” These disposable products feature thin sheets of coated adhesive that trap contaminants. Once the top sheet is saturated, it is peeled off to reveal a clean sheet underneath.

| Pros | Cons |

| Low-cost

Easy install Versatile sizing and tack levels Personnel don’t need to wear PPE |

Often too small

Lose effectiveness during use Not suitable for wheels Particulates can cause cross-contamination Wasteful Trip hazard Replacements are costly Leftover adhesive needs to be removed before reapplication |

Pros

- Low-Cost: Sticky mats offer a solution with a low upfront cost, which fits into your operational expenditure (OPEX) budget.

- Easy to Use: Sticky mats are simple to install and require minimal maintenance. They can be easily replaced once they become soiled or lose their tackiness.

- Versatility: These mats are available in various sizes and tack levels, making them suitable for different environments and applications.

- Non-Invasive: Sticky mats do not require special footwear or equipment, allowing personnel to move freely without additional gear.

Cons

- Size: Sticky mats are often not big enough (on average, 3 x 2 feet) to decontaminate shoes and wheels effectively. A singular sticky mat is only about 27% effective.

- Particle Build-Up: Sticky mats immediately lose effectiveness as contamination accumulates, especially with repeated steps in the same area. Contaminants clinging to footwear can transfer back onto the shoe and spread to other places, heightening the risk of contamination in critical environments.

- Wheeled Traffic: Sticky mats are not suitable for areas with wheeled traffic. They are prone to wrapping around the wheels and tearing, and the adhesive from the mat is often transferred via the wheels into the cleanroom or controlled area.

- Particle Shedding: When you peel the top layer of a sticky mat, on average, 125,000 particles are distributed into the environment, resulting in the area being re-contaminated.

- Waste: Removing a layer from a sticky mat generates an 8-inch (20 cm) ball of contaminated waste. As a result, this waste fills several dumpsters every year. Sticky mats are considered secondary waste, requiring proper disposal, which can incur significant costs.

- Health & Safety: Sticky mats pose a risk to health and safety due to their potential to create a trip hazard.

- Long-Term Cost: Although the initial upfront cost seems low, over time, the costs from regular replacement and disposal, as well as risks associated with sticky mats, can increase dramatically.

- Adhering to Subfloor: Difficulties with sticky mats often arise when keeping the mats adhered to the subfloor. When the last sticky mat from the stack is used, the adhesive left behind on the floor must be painstakingly cleaned before a new stack can be put down. Otherwise, the new contamination control flooring will not stick properly and move around.

Footbaths & Sanitizing Mats

Commonly used in food and beverage facilities, footbaths are filled with a liquid sanitizing solution or sanitizing powder to decontaminate footwear before entering production areas.

| Pros | Cons |

| Full contamination control

Antimicrobial |

Must be used for an extended time

Can cause cross-contamination if not maintained Requires a lot of cleaning Initial investment and ongoing costs |

Pros

- Full Decontamination: Footbaths and sanitizing mats enable decontamination to the very edges of the shoe and between treads.

- Antimicrobial: They are often filled with antimicrobial chemicals that disinfect footwear upon entry and exit.

Cons

- Contact Time: Footbaths and sanitizing mats use chemical disinfectants for decontamination, but personnel must allow adequate contact time (on average 5 minutes) for them to work. If there is an excessive build-up of organic material, sanitizers may become less effective.

- Cross-Contamination: Improperly maintained or used footbaths and sanitizing mats can do more harm than good. Neglected footbaths may breed harmful bacteria, while incorrect chemical concentrations increase the risk of particles on shoes.

- Employee Downtime: Maintaining footbaths and sanitizing mats involves multiple steps, including monitoring, replenishing, cleaning, and disposing of contaminated materials, demanding frequent attention from operators or janitorial staff.

- Cost: The initial investment and ongoing expenses, including disposal, can accumulate rapidly, particularly for larger facilities with increased foot traffic and production.

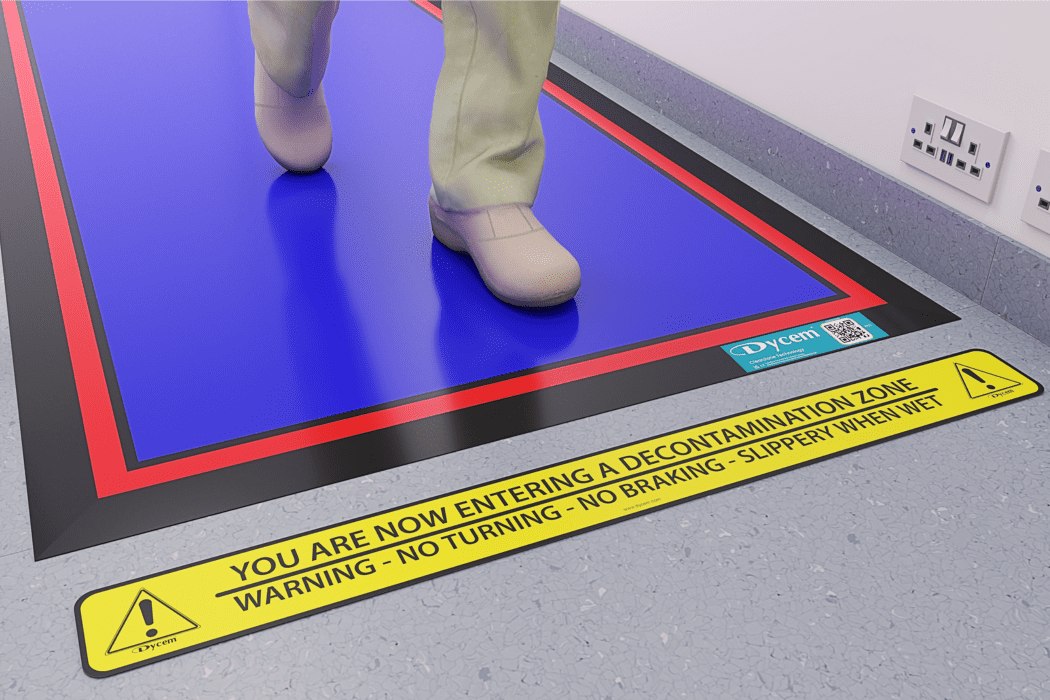

Dycem Mats

Dycem’s reusable contamination control mats are used in cleanrooms and controlled environments to capture up to 99% of contamination from shoes and wheels. They have a washable, natural, tacky surface lasting 3+ years.

| Pros | Cons |

| High rates of contamination control

Suitable for long-term use Custom design Requires minimal training to use Antimicrobial properties Effective on wheel contamination |

Initial cost

Require maintenance |

Pros

- Effective: Dycem mats are proven to capture and retain up to 99.9% of contamination from shoes and wheels and up to 75% of airborne contamination.

- Sustainable: The washable mats last for 3+ years, offering a long-term solution that can replace single-use alternatives, reducing your company’s carbon footprint.

- Customizable: Dycem mats are custom-designed for each customer to achieve the most effective results.

- User-Friendly Size: Dycem mats are installed in the unavoidable traffic flow, and employees require minimal training. They simply cross the surface, reducing downtime and human error.

- Antimicrobial: All Dycem products incorporate Biomaster, an antimicrobial additive that uses silver ion technology to proactively inhibit and disrupt microorganisms’ growth.

- Wheeled Traffic: Dycem mats are the ONLY effective solution for contamination control for heavy-wheeled traffic.

Cons

- High Upfront Cost: Dycem mats have a higher initial cost than disposable mats. While they are more cost-effective in the long run due to their durability and reusability, the upfront investment can be a barrier for some.

- Maintenance Requirements: While Dycem mats are easy to clean, they require regular maintenance to ensure optimal performance. Failure to maintain them properly may reduce their effectiveness in trapping contaminants

Use our compliance comparison document to determine if your contamination control solutions meet the external regulatory and auditory requirements.

Floor Level Contamination Control Solutions with Dycem

To reduce floor-level contamination in your facility, consider Dycem mats and products. At Dycem, we offer various floor contamination control methods tailored to multiple industries, ensuring cleaner environments and improved safety. Contact us today to explore our range of products and learn how Dycem can help you achieve optimal contamination control.