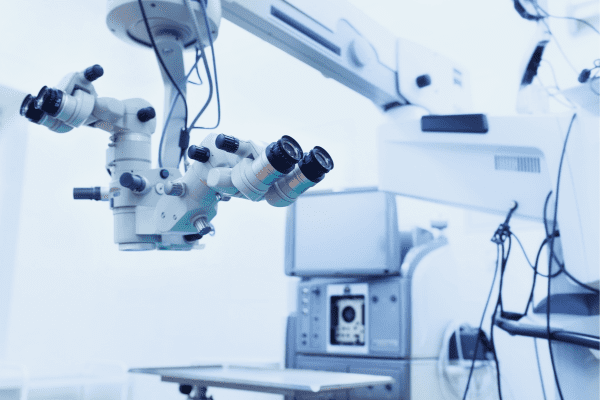

Plastikos is a plastic injection molding company that specializes in medical device manufacturing through ISO 7 & ISO 8 cleanrooms and dedicated white room space. They are committed to providing high-quality products and services to their customers with a focus on innovation and sustainability. Setting the industry standard for excellence since 1978, they remain true to their pioneering nature and core values.

CHALLENGE

Plastikos decided to retrofit a white room to an ISO 8 space, and retrofitting a cleanroom is never easy. With cleanliness in mind, two main concerns came up – the safety of their employees and controlling foreign particulate – they had to find a solution. Previously, Plastikos had been using and peeling sticky mats 12 to 15 times a shift, which posed a tripping hazard and were “very unsightly”.

With the foreign particulate still being a concern, they conducted a root cause evaluation to assess the contamination risks and identify the source of the problem. They determined human and workflow traffic patterns through their busiest environment was a challenge that prompted the search for a new method to control contamination at the floor level.

SOLUTION

Their local Dycem specialist conducted a site survey and Plastikos started with a trial of the product to assess how the mats would hold up in a heavy, plastic injection, molding environment. To identify the best placement for the mats, they segregated the areas that received the most traffic.

After the trial period was conducted, Dycem and Plastikos were able to evaluate the new traffic patterns and determined that switching from CleanZone to WorkZone flooring was the best course of action. The trial period was “one of the most significant factors”, as the WorkZone flooring was able to withstand the pellets of the hard polymer that made their way onto the floor.

RESULTS

The results were instantaneous; the employees were delighted. No longer did they have to struggle with removing the sheets from sticky mats, and maintenance was able to be far more efficient with a streamlined cleaning process, only needing to clean the mats once per shift. Plastikos continues to conduct regular particulate testing and is pleased with the safety and performance of the Dycem material.

“Dycem has great customer service, they helped me to better understand the product” – John Williams, Molding Manager

ABOUT PLASTIKOS

By providing specialized components that are integral to today’s healthcare industry, Plastikos helps deliver life-changing innovation to those who need it most. Their key niche markets include medication delivery systems, surgical eye care, testing & diagnostics, among others.