Consuming food and beverages constitutes an essential aspect of daily life for everyone. Yet, few individuals contemplate the origin and conditions of food production and the need for contamination control in the food industry. This places a substantial obligation on food and beverage manufacturers to uphold contamination-free environments in their production, packaging, and storage facilities.

Unfortunately, instances of inadequate contamination control in the food industry are not uncommon. Recent recalls of products from Ferrero and Tesco underscore this concern. A salmonella outbreak among young children prompted the recall of ‘Kinder Surprise’ chocolate eggs and the temporary closure of one of Ferrero’s factories for investigation. Similarly, Tesco had to withdraw their free-from digestive biscuits from shelves due to potential metal contamination. These recalls can severely harm a business’s reputation and financial stability. Moreover, contaminated food items pose significant health and safety risks to consumers.

Different Types of Contamination in the Food Industry

Contamination can manifest at various stages of the food and beverage production process, encompassing manufacturing, packaging, storage, and transportation. An article in Nutritional Outlook Magazine identifies three prevalent types of contamination within the food and beverage industry:

- Cross-contamination arises when multiple types of products are manufactured in the same facility. This often results from improper equipment sterilization or inadequate segregation of production areas.

- Particle contamination occurs when visible or invisible particles infiltrate critical spaces. These particles may be introduced by personnel, such as skin, hair, or clothing particles. Additionally, airborne particles like pollen, spores, and dust mites can contribute to contamination.

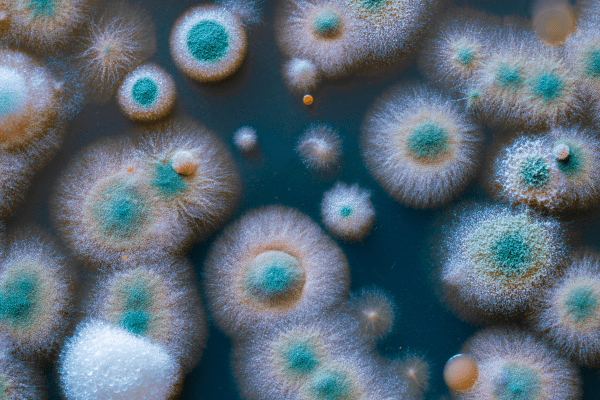

- Microbial contamination transpires when microorganisms, including bacteria, mold, fungi, viruses, and toxins, compromise food and beverage products. This can be attributed to poor hygiene practices, improper handling of raw meat, or suboptimal storage temperatures.

Contamination Control Strategies

Addressing these contamination concerns is paramount for any food and beverage facility. To mitigate contamination risks, several strategies can be employed:

- Implementation of air filtration systems and zoning protocols

- Comprehensive staff training in proper hygiene and gowning procedures

- Rigorous sanitization during entry and exit from critical areas

- Thorough machinery cleaning and ongoing maintenance

- Adoption of Dycem flooring

Preventing contamination is far more cost-effective than dealing with the potential consequences within a food and beverage manufacturing environment.

How Dycem Can Help With Contamination Control in the Food Industry

Dycem offers a crucial contamination control solution for such facilities. A substantial 80% of contaminants enter critical zones via footwear and wheels, making effective control imperative in this regard.

Dycem’s flooring, inherently adhesive, thwarts up to 99.9% of particle contamination from feet and wheels, safeguarding critical areas. Its high surface energy further captures and retains up to 75% of airborne particles, bolstering contamination prevention.

All Dycem products integrate Biomaster Antimicrobial Technology, leveraging silver ion technology to inhibit the growth of over 50 microorganisms on contact, including Salmonella, E. coli, and Listeria.

Dycem flooring is available in customizable options and various colors, such as red and green, facilitating zoning strategies to differentiate ‘high-risk’ and ‘low-risk’ zones for staff.

Prominent entities in the food and beverage sector, including Nestle, Müller, Coca-Cola, and Heinz, benefit from our support. If contamination control is a concern in your facility, don’t hesitate to reach out. Our contamination control specialists are eager to discuss your options.