Pharmaceutical & Biotechnology

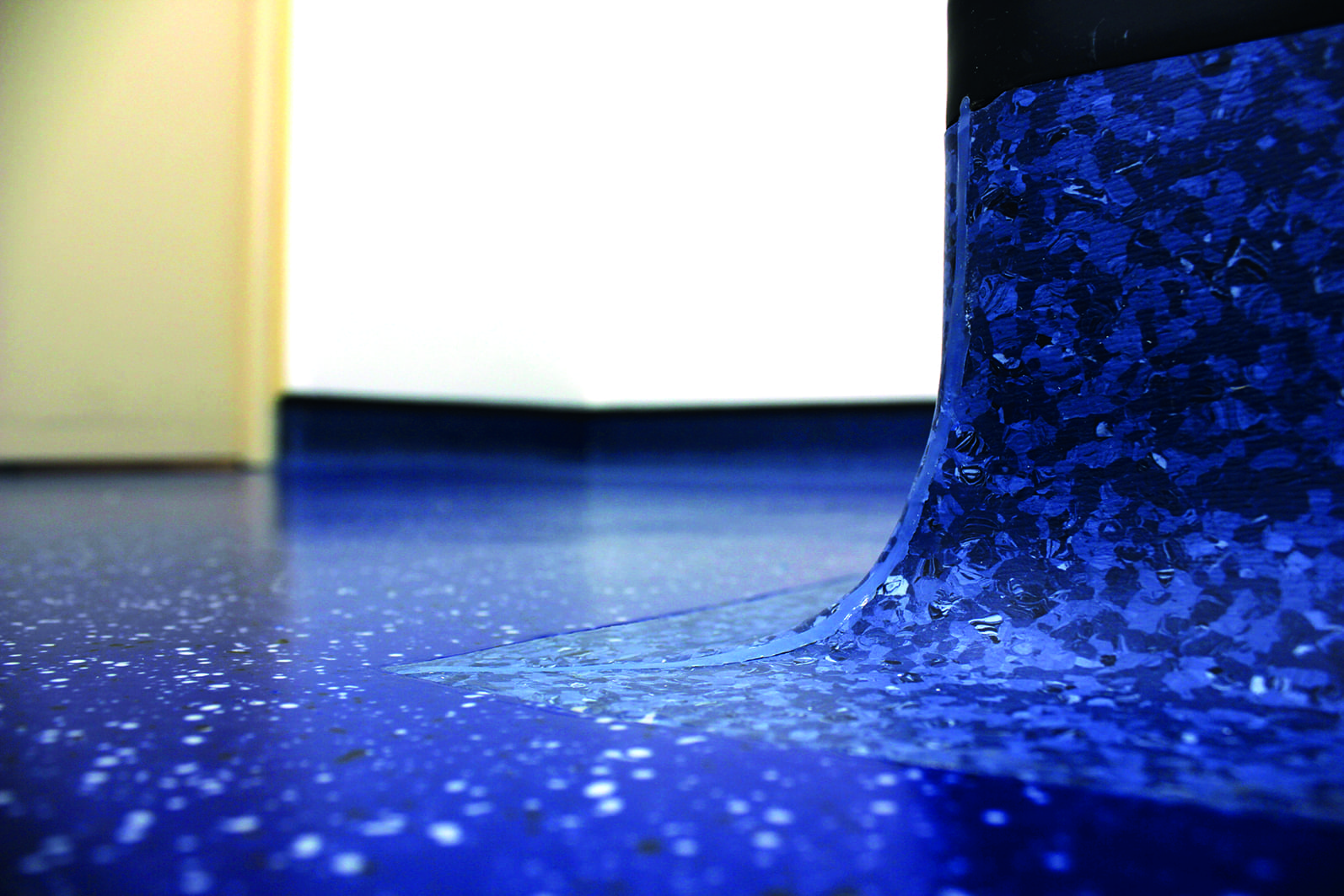

Efficacy and quality control in drug and biologics manufacturing requires a comprehensive strategy that includes prevention, monitoring, and a stringent process for addressing contamination. With a well-established and proven track record, Dycem offers a unique solution to help combat contamination at floor level and serves as a valued partner to leaders within the pharmaceutical & biotechnology industry. pharmaceutical flooring

Where to use Dycem in the pharmaceutical & Biotechnology Industry

Gown rooms and personnel airlocks.

Material airlocks.

Product transfer areas.

Cleanrooms exits and multifunctional corridors.

Primary packaging/ Assembly areas.

CNC Warehouses.

Contamination: The Risk to the Pharmaceutical & Biotechnology Industry

Because of the highly critical nature of certain products, Good Manufacturing Practices (GMP) were developed and implemented as a system to ensure consistency and control in quality standards. A major aspect of the principles of GMP guidelines is a focus on the cleanliness of facilities and equipment to prevent contamination at the floor level. A robust contamination control strategy ensures products are of the highest quality, meet regulatory requirements by the Federal Drug Administration (FDA) and other governing bodies, and do not compromise the health & safety of end users. During manufacturing, contamination can be introduced from facility personnel, raw materials, equipment, and processes.

Common types of contamination found throughout the manufacture of drugs and biologics include visible particles like dust, debris, hair, and fibers, as well as invisible particles such as skin cells, cosmetics, and microbes. The outcomes of a contamination occurrence include threats to health & safety, quarantined batches, product recalls, and factory shutdowns. pharmaceutical flooring

The risks to a company’s brand, its profitability, and its people are too consequential to be ignored. Effective contamination control at floor level is essential for facilities adhering to GMP guidelines.

Dycem mats, implemented as part of a contamination control strategy, offer optimal support in reducing the risk of contamination in the pharma and biotech industry. pharmaceutical flooring

Don't Ignore the Floor...

80% of Contamination Enters a Critical Space at Floor Level.

Benefits of Dycem in the Pharmaceutical & Biotechnology Industry

80% of contamination enters a critical space at floor level.

superior Particle collection & retention

Both visible and invisible particulates from shoes and wheels are captured on Dycem mats and remain on the surface until cleaned off. Benefit from a reduction in floor-level particulate of up to 99.9% and a reduction in air particulate levels of up to 75% with Dycem.

Reduce microbial contamination concerns

With Dycem mats installed prior to critical areas, our pharmaceutical & biotechnology customers have peace of mind that damage from microbial contamination is minimized. All Dycem products contain Biomaster, an active antimicrobial additive. pharmaceutical flooring

cost-effective, sustainable alternative

Unlike disposable contamination control solutions, Dycem mats last on average 3+ years. Pharmaceutical & biotechnology manufacturers typically see an ROI shortly after purchase, as well as the added benefit of a reduced carbon footprint due to less plastic waste. pharmaceutical flooring

Our Products, Your Industry

From the initial stages of API production, milling, and granulation, all the way through to tablet pressing, fill & finish, and sterile packaging, it is crucial to maintain high standards of quality and cleanliness at every step of drug and biologic production. Dycem’s highly effective contamination control solutions support the many complex products and processes in the pharmaceutical & biotechnology industry. Keeping contamination out of critical spaces and cleanrooms is our priority. pharmaceutical flooring

Dycem CleanZone

CleanZone helps control contamination from the shoes of personnel.

Dycem WorkZone

WorkZone is the only effective solution for decontamination of heavy wheels.

In Your Industry

Discover your industry’s specific applications—all conveniently summarized right here.

Success Stories...

Discover our success stories in your industry.

Learn how our customers have benefitted from installing Dycem. pharmaceutical flooring

Structuring your Contamination Control Strategy with Dycem

Read the following article from Dr. Tim Sandle and RSSL. pharmaceutical flooring

“A contamination control strategy (CCS) is a system that considers all the integral elements of pharmaceutical product manufacturing. A CCS should cover:

- Microbial contamination

- Cleaning and disinfection

- Sterility assurance

- Facility design

- Chemical and particle contamination

- Other forms of contamination that can arise from mix-ups, damaging primary or secondary packaging, distribution problems, and environmental fluctuations”